Mill-Pro supplies a full range of PE100 Flange adaptors (Stub Flanges) manufactured by injection moulding from our own tooling or machined from extruded hollow bar, in accordance with ISO 9624.

- Flange Adaptor is a standard PE stub only, complying to ISO 9624, without a backing flange.

- Flange Assembly is a PE stub or PE full-face stub, complete with a matching loose backing ring sold as a single item. Our Full Face flange adaptor assemblies are a proprietary Mill-Pro design, they are only sold complete with the matching backing flange.

Flange Adaptors are available from 90mm OD (DN80) to 2000mm OD (DN1800) in pressure ratings from PN4 to PN25. Mill-Pro flange adaptors are designed with extra-long spigots to allow assembly and disassembly using standard bolts after the spigot is fused in position, even when using long series Electrofusion couplers.

Standard loose backing flanges comply to BSEN 1092-1 PN16 drilling and ring thickness. However, other drillings, pressure ratings and dimensions, such as ANSI, JIS, AS/NZS to match other equipment can also be supplied. Loose backing flange materials include:

Mild steel coated with Fusion Bonded Epoxy (FBE) a Polymeric anti-corrosion (Barrier) coatings for buried applications, Mill-Pro's coatings are applied and tested in accordance with the UK Water Industry Standard WIS 4-52-01 and 1994 Amendment WIS 4-52-01 WIS 4-52-01a

Stainless Steel for exposure above ground and in marine environments, click here for Stainless Steel grade recommendations.

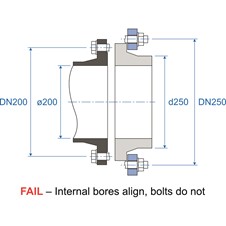

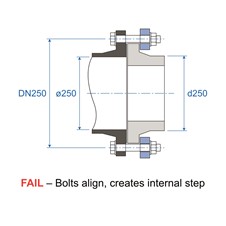

CONNECTING PE FLANGES TO STEEL & DUCTILE IRON FLANGES IN SIZES ≥ DN200

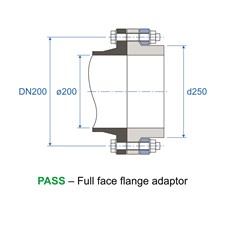

In larger sizes (≥ DN200) flange drilling patterns between standard PE and DI flanges no longer line up with the nominal bore of Ductile Iron (DI) or steel pipe sizes. This is especially true of PE pipes ≤ SDR11, due to its significant wall thickness in larger diameters. So a Full Face flange adaptor (slim flange adaptor) must be used to make the connection.

Full Face flange adaptors are designed to align the internal bore of Polyethylene pipes, with the equivalent nominal size Ductile Iron valve or fitting at a flanged connection joint. In smaller sizes, ≤ DN150 the internal diameters of PE and DI line up (within < 10%) of standard PE ISO 9624 flange adaptors, so Full Face are not required. Click on the illustrations below to understand why Full Face flange adaptors are required DN200 and above.

Note 1: Full-face flange adaptor designs are proprietary. Each supplier has its own design, however, Hong Kong Water Supplies Department (WSD) PS2 Clause 5.10 specifies dimensional and testing requirements for flange adaptors, including the provision of Type Testing (TT) results for a suppliers design in accordance with BSEN 12201-3 Table 4: Hydrostatic strength test at 80º C for 1000 hours. This is essential to demonstrate the supplier's design will perform leak-free long term.

Note 2: Fusion Bonded Epoxy (FBE) coating on loose backing rings is not recommended for prolonged direct UV exposure, due to the chalking effect occurring over time when epoxies are exposed to UV.