Air Valve Offtakes

There are many different configurations and connection methods possible when making air valve connections on PE pipelines. Typically reducing tees or saddles, the choice of which depends if they are being installed as part of the construction (reducing tee) or fitted after the pipeline has been constructed (saddles). WSD Appendix does not cover the use of saddles.

Modern Air Valves (Tripple Function Air valves) provide the following three functions in a water supply pipeline:

Degassing - the continuous release of small quantities of air bubbles which are created during normal pipeline operation, due to pressure and temperature change.

Air release - the infrequent release of large quantities of air, typically as the pipeline is being filled.

Vacuum break - allowing atmospheric air back into the pipeline when it is being drained. This prevents the pipeline from collapsing under vacuum conditions and provides efficient draining of the pipeline.

Design notes: All PE pipes regardless of size, with an SDR rating of 17 or less, can structurally withstand a complete vacuum (-100Kpa) without buckling. For more information on high-performance Air Valves for water supply and sizing air valves, refer to the Bayard / Talis web site or contact us for datasheets on Bayard Air valves.

The examples below are designed help designers select the most appropriate method to make an air valve connected to a PE pipeline. Generally, the main considerations are:

- Air valve size: DN 50, 80, 100, 150*, 200* (* sizes are uncommon)

- Air valve connection method: Threaded (DN50) or Flanged (DN80, 100, 150).

- Pipe offtake method: Using an electrofusion saddle or cutting a tee into the pipeline.

- Connection type: Direct connection above the pipeline, Alternate connection away from the pipeline (typically due to space constraints above the pipeline).

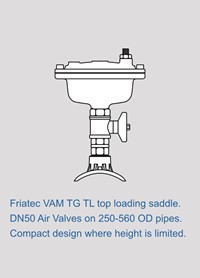

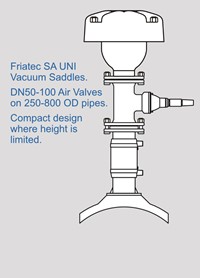

Electrofusion Saddles such as the Friatec VAM top-loading saddle or Friatec spigot saddles are perfect for installing air valves at the actual high points after the pipeline has already been installed (see a case study here). Saddles also provide the most compact solution, minimising height from the crown of the pipe to the top of the air valve when using the direct connection method below.

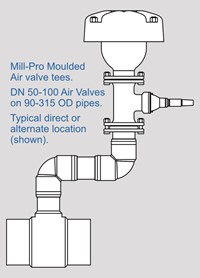

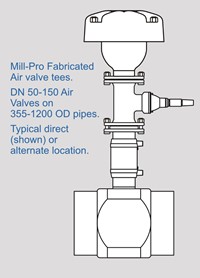

Reducing Tees are commonly used during pipeline construction. Reducing tees can be installed as a standard PE fitting in the pipeline, with a flange adaptor electrofused to the tee's off-take in order to connect the isolation valve and air valve assembly. In this case, either injection moulded reducing tee or a PE fabricated tee would be used.

The examples below provide typical suggested connection methods, depending on the air valve size, the PE pipe size and connection circumstances. For more detailed information on Air Valve connections and Air Valves email us or chat below.