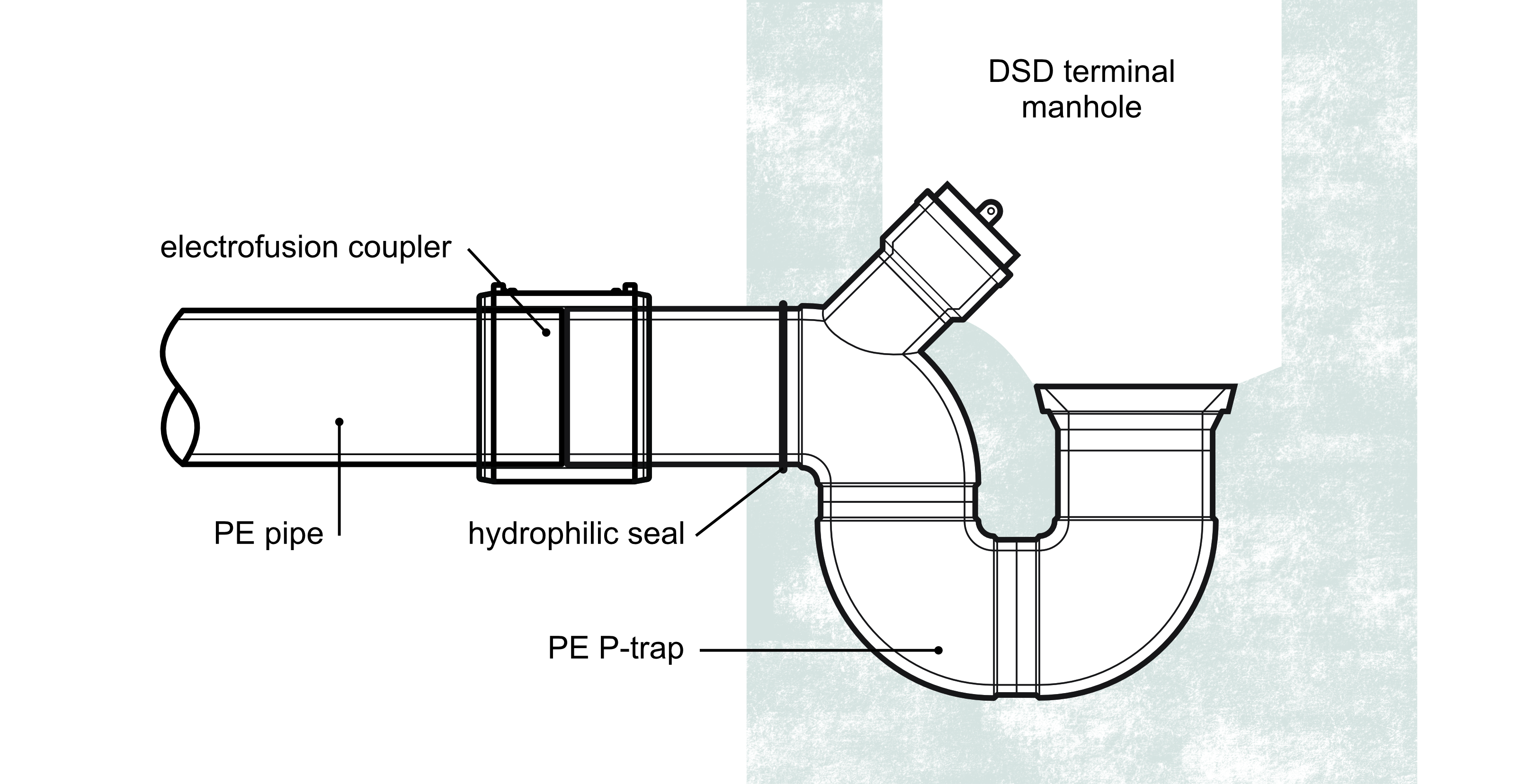

Terminal Manhole Connection / P-Trap

Typically referred to as a P-trap, this is a fully structural fabricated polyethylene equivalent, to a traditional cast iron P-trap. It shares similar dimensions to traditional Cast Iron P-Trap's and meets the requirements given in the following DSD drawings:

DS1053C, DS1055E, DS1058D, DS1092, DS1093, DS1094, DS1090 - Terminal Manhole Type T1.

P-traps are installed at the base of terminal manholes to prevent sewer gas (H2SO4) and odours escaping from the manhole (such as the last manhole inside buildings). PE P-Trap's have an expected life of 100 years. Cast Iron P-Traps need replacing after 15-20 years of service due to internal corrosion.

Mill-Pro PE P-Traps are supplied with a rubber ring sealed PE plug at the rodding eye inlet, chain loop and a stainless steel chain/wire connection to fix the plug to the chamber wall.

When PE is cast into concrete there is no adhesion between PE and cement. Due to thermal expansion of the PE during concrete curing, there is a small gap between the PE and the cured concrete after cooling. This gap allows wastewater to leak past the PE fitting. A Hydrophilic seal is fitted where the PE exits the concrete, this seal expands up to 600% when wet to seal the PE and concrete chamber walls.

If you are connecting PE pipes to an existing Cast Iron P-Trap click here

Polyethylene P-trap installation

Mill-Pro Polyethylene P-Traps are a fully structural fabrication, due to the exclusive use of butt welding. Therefore no anchoring is required, the connecting PE pipe is electrofused directly to the spigot of the Polyethylene P-Trap, which is cast into the manhole chamber. The P-Trap can take full tensile load once cast into the chamber wall. This is the lowest cost option for a terminal manhole and provides a maintenance free drainage system.

Click for submission document and installation instructions for a: PE P-Trap Submission Doc

Polyethylene P-Trap Manufacturing

-

CCTV Spigot end for EF welding

-

-

DN450 x 150 for Hong Kong

-

Butt weld spigot for rodding eye

-

Fabrication using only Butt welds

-

(Note: Image is legacy design)

All Mill-Pro P-Traps are manufactured using only Butt Welding techniques in accordance with BS ISO 21307, including on the rodding connection. Extrusion welding is NOT structural and is weak, it is banned under DSD PS Appendix 5A, Clause 5.4 PS Appendix 5A

Extrusion welding is never used on Mill-Pro PE fittings - All P-Traps are structurally rated for full tensile load.

Read more here about the difference between extrusion & butt welding