Black Tapping / Spigot Saddles

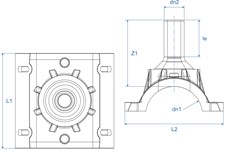

Black Tapping Tee / DAA / PN16 / SDR11

Friatec self-tapping tee for making live connections into PE water mains in PN10 and PN16. DAA self-tapping tees feature an Integrated drill with solid upper and lower stop and torque limiter for protection against excessive force. New and innovative over centre clamping system does not require any tools for installation on to the pipe. Execution of the tapping requires a hexagonal wrench key with a wrench (size 17). Anti-tamper fusion cap available to prevent unauthorised shut off.

Features an extra-long spigot outlet to allow a secondary fusing to the same spigot to accommodate future changes.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

|

WSD PS does not cover connections using self-tapping saddles. |

|||||||||

|

Product Code |

dn1 |

dn2 |

da |

L1 |

L2 |

le |

Z1 |

Z2 |

Availability in Hong Kong |

|

P3316.85.050025 |

50 |

25 |

25 |

136 |

95 |

83 |

37 |

125 |

8-12 Weeks |

|

P3316.85.050032 |

50 |

32 |

25 |

136 |

95 |

86 |

37 |

128 |

8-12 Weeks |

|

P3316.85.063025 |

63 |

25 |

25 |

146 |

108 |

83 |

51 |

118 |

8-12 Weeks |

|

P3316.85.063032 |

63 |

32 |

25 |

146 |

108 |

86 |

51 |

123 |

8-12 Weeks |

|

P3316.85.063063 |

63 |

63 |

30 |

146 |

108 |

115 |

51 |

165 |

8-12 Weeks |

|

P3316.85.090025 |

90 |

25 |

30 |

170 |

137 |

83 |

66 |

123 |

8-12 Weeks |

|

P3316.85.090032 |

90 |

32 |

30 |

170 |

137 |

86 |

66 |

126 |

8-12 Weeks |

|

P3316.85.090063 |

90 |

63 |

30 |

170 |

137 |

115 |

66 |

168 |

8-12 Weeks |

|

P3316.85.125025 |

125 |

25 |

30 |

170 |

167 |

83 |

83 |

131 |

8-12 Weeks |

|

P3316.85.125032 |

125 |

32 |

30 |

170 |

167 |

86 |

83 |

138 |

8-12 Weeks |

|

P3316.85.125063 |

125 |

63 |

30 |

170 |

167 |

115 |

83 |

180 |

8-12 Weeks |

|

P3316.85.180025 |

180 |

25 |

30 |

186 |

203 |

83 |

116 |

132 |

8-12 Weeks |

|

P3316.85.180032 |

180 |

32 |

30 |

186 |

203 |

86 |

116 |

141 |

8-12 Weeks |

|

P3316.85.180063 |

180 |

63 |

30 |

186 |

203 |

115 |

116 |

188 |

8-12 Weeks |

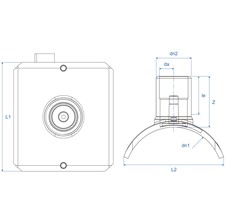

Black Tapping Tee / DAA TL / PN16 / SDR11

Friatec self-tapping tee for making offtake connections in larger size PE water mains in PN10 and PN16. DAA TL tees feature an Integrated drill. Installation can be either during construction or post-construction when the pipeline is under normal operating pressure. This prevents the main having to be shut down during the installation process.

The DAA TL must be installed using a top-loading clamping unit, to apply and maintain force on the saddle during the fusing and cooling period. The Top Loading unit is available for rental. Execution of the tapping requires a hexagonal wrench key with a wrench (size 17). Anti-tamper fusion cap available to prevent unauthorised shut off.

Pressure test of the saddle after fusion is recommended, before drilling the tapping hole into the main pipe.

Features an extra-long spigot outlet to allow a secondary fusing to the same spigot to accommodate future changes.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| WSD PS does not cover connections using self-tapping saddles. | |||||||

|

Product Code |

dn1 |

dn2 |

da |

L1 |

le |

Z2 |

Availability in Hong Kong |

|

P3316.87.250-315063 |

250-315 |

63 |

30 |

195 |

118 |

180 |

8-12 Weeks |

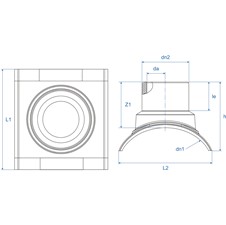

Black Spigot Saddle / SA / PN16 / SDR11

The Friatec SA electrofusion spigot saddles with bolt-on underpart can be installed during construction or post-construction when the pipeline is under normal operating pressure. Connections can be made 'live' using under pressure tapping equipment. This prevents the main having to be shut down during the installation process.

Pressure test of the saddle after fusion is recommended before drilling the tapping hole into the main pipe.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| WSD PS does not cover connections using electrofusion saddles. | |||||||

|

Product Code |

dn1 |

dn2 |

L1 |

L2 |

le |

Z1 |

Availability in Hong Kong |

|

P3316.083.125063 |

125 |

63 |

185 |

190 |

63 |

109 |

8-12 Weeks |

|

P3316.083.125090 |

125 |

90 |

185 |

185 |

79 |

116 |

8-12 Weeks |

|

P3316.083.180063 |

180 |

63 |

195 |

240 |

63 |

100 |

8-12 Weeks |

|

P3316.083.180090 |

180 |

90 |

285 |

241 |

79 |

116 |

8-12 Weeks |

|

P3316.083.180125 |

180 |

125 |

285 |

241 |

87 |

141 |

8-12 Weeks |

Black Spigot Saddle / SA TL / PN16 / SDR11

The Friatec SA TL electrofusion spigot saddles can be installed during construction or post-construction when the pipeline is under normal operating pressure. Connections can be made 'live' using under pressure tapping equipment. This prevents the main having to be shut down during the installation process.

The SA TL must be installed using a top-loading clamping unit, to apply and maintain force on the saddle during the fusing and cooling period. The Top Loading unit is available for rental.

Pressure test of the saddle after fusion is recommended, before drilling the tapping hole into the main pipe.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| WSD PS does not cover connections using saddles. | ||||||

|

Product Code |

dn1 |

dn2 |

L1 |

le |

Z1 |

Availability in Hong Kong |

|

P3316.187.250-560032 |

250-560 |

32 |

200 |

42 |

109 |

8-12 Weeks |

|

P3316.187.250-560063 |

250-560 |

63 |

200 |

56 |

109 |

8-12 Weeks |

|

P3316.187.250-560090 |

250-560 |

90 |

200 |

80 |

111 |

8-12 Weeks |

Black Spigot Saddle / SA UNI / PN16 / SDR11

The Friatec SA UNI electrofusion spigot saddles can be installed during construction or post-construction when the pipeline is under normal operating pressure. Connections can be made 'live' using under pressure tapping equipment. This prevents the main having to be shut down during the installation process.

Pressure test of the saddle after fusion is recommended, before drilling the tapping hole into the main pipe via integrated pressure nozzle and pressure test adaptor - FWDPA.

Assembly is conducted using the FRIATOOLS clamping unit UNITOP. Tapping in the unpressurised condition can be achieved using the correct size hole saw.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| WSD PS does not cover connections using saddles. | ||||||||

|

Product Code |

dn1 |

dn2 |

da |

L1 |

L2 |

le |

Z1 |

Availability in Hong Kong |

|

P3316.187.250-28090 |

250-280 |

90 |

66 |

260 |

279 |

79 |

130 |

8-12 Weeks |

|

P3316.187.250-280125 |

250-280 |

125 |

94 |

260 |

279 |

87 |

146 |

8-12 Weeks |

|

P3316.187.315-40090 |

315-400 |

90 |

66 |

280 |

279 |

79 |

130 |

8-12 Weeks |

|

P3316.187.315-400125 |

315-400 |

125 |

94 |

280 |

279 |

87 |

146 |

8-12 Weeks |

|

P3316.187.450-80090 |

450-800 |

90 |

66 |

307 |

279 |

79 |

130 |

8-12 Weeks |

|

P3316.187.450-800125 |

450-800 |

125 |

94 |

307 |

279 |

87 |

146 |

8-12 Weeks |

Black Spigot Saddle / SA XL / PN16 / SDR11

The Friatec SA XL electrofusion spigot saddles are used for making large diameter offtakes (up to dn355) on large diameter PE mains up to dn1200. The SA XL can be installed during construction or post-construction when the pipeline is under normal operating pressure. Connections can be made 'live' using under pressure tapping equipment. This prevents the main having to be shut down during the installation process.

Pressure test of the saddle after fusion is recommended, before drilling the tapping hole into the main pipe.

Assembly is conducted using a FRIATOOLS vacuum pump and the corresponding FRIATOOLS plunger. The vacuum unit sucks the saddle down onto the surface of the pipe providing the necessary force to achieve optimal electrofusion to the pipe surface. Tapping in the unpressurised condition can be achieved using the correct size hole saw.

NOTE: The pipe surface must be prepared in accordance with the general installation instructions using a mechanical saddle peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| WSD PS does not cover connections using saddles. | |||||||||

|

dn1 |

dn2 |

da |

h |

L1 |

L2 |

le |

Z1 |

Availability in Hong Kong |

|

|

P3316.187.400250 |

400 |

250 |

187 |

261 |

530 |

417 |

210 |

483 |

8-12 Weeks |

|

P3316.187.450250 |

450 |

250 |

187 |

272 |

530 |

426 |

210 |

530 |

8-12 Weeks |

|

P3316.187.500250 |

500 |

250 |

187 |

263 |

530 |

380 |

210 |

521 |

8-12 Weeks |

|

P3316.187.500315 |

500 |

315 |

254 |

268 |

590 |

446 |

210 |

573 |

8-12 Weeks |

|

P3316.187.560250 |

560 |

250 |

187 |

263 |

530 |

398 |

210 |

577 |

8-12 Weeks |

|

P3316.187.560315 |

560 |

315 |

254 |

268 |

590 |

402 |

210 |

564 |

8-12 Weeks |

|

P3316.187.560355 |

560 |

355 |

286 |

260 |

630 |

451 |

210 |

618 |

8-12 Weeks |

|

P3316.187.630250 |

630 |

250 |

187 |

267 |

530 |

419 |

210 |

634 |

8-12 Weeks |

|

P3316.187.630315 |

630 |

315 |

254 |

265 |

590 |

417 |

210 |

621 |

8-12 Weeks |

|

P3316.187.630355 |

630 |

355 |

286 |

269 |

630 |

422 |

220 |

616 |

8-12 Weeks |

|

P3316.187.710250 |

710 |

250 |

187 |

265 |

530 |

437 |

210 |

712 |

8-12 Weeks |

|

P3316.187.710315 |

710 |

315 |

254 |

268 |

590 |

439 |

210 |

694 |

8-12 Weeks |

|

P3316.187.710355 |

710 |

355 |

286 |

285 |

630 |

457 |

220 |

694 |

8-12 Weeks |

|

P3316.187.800250 |

800 |

250 |

187 |

275 |

530 |

384 |

210 |

643 |

8-12 Weeks |

|

P3316.187.800315 |

800 |

315 |

254 |

268 |

590 |

377 |

210 |

629 |

8-12 Weeks |

|

P3316.187.800355 |

800 |

355 |

286 |

290 |

630 |

483 |

220 |

772 |

8-12 Weeks |

|

P3316.187.900250 |

900 |

250 |

187 |

278 |

530 |

402 |

210 |

714 |

8-12 Weeks |

|

P3316.187.900315 |

900 |

315 |

254 |

269 |

590 |

393 |

210 |

700 |

8-12 Weeks |

|

P3316.187.900355 |

900 |

355 |

286 |

305 |

630 |

429 |

220 |

700 |

8-12 Weeks |

|

P3316.187.1000250 |

1000 |

250 |

187 |

280 |

530 |

366 |

210 |

653 |

8-12 Weeks |

|

P3316.187.1000315 |

1000 |

315 |

254 |

270 |

590 |

358 |

210 |

642 |

8-12 Weeks |

|

P3316.187.1000355 |

1000 |

355 |

286 |

305 |

630 |

444 |

220 |

774 |

8-12 Weeks |

|

P3316.187.1200250 |

1200 |

250 |

187 |

280 |

530 |

354 |

210 |

655 |

8-12 Weeks |

|

P3316.187.1200315 |

1200 |

315 |

254 |

270 |

590 |

343 |

210 |

645 |

8-12 Weeks |

|

P3316.187.1200355 |

1200 |

355 |

286 |

305 |

630 |

413 |

220 |

759 |

8-12 Weeks |