Puddle Flanges

Black Puddle Flange / Long Spigot / PN16 / SDR11 / with optional Waterstop

Puddle flanges perform the same function as their Ductile Iron (DI) counterparts. Designed for encasement in concrete, where PE passes through a structure (typically a concrete wall). Because PE is an 'end to end system' in respect to the transfer of forces (pressure, thermal and ground movement). A puddle flange design must withstand loads that exceed the ultimate tensile strength of the pipe meaning Pipe fails first in a tensile pull to failure.

For this reason, Mill-Pro puddle flanges are either injection moulded in PE100+ or machined from a single piece of extruded PE100+ hollow bar. They contain no welds or joints in the puddle area. (between the tapered sections).

In reclaimed land applications (for which PE is perfectly suited to), designers must consider to total lateral force that may be applied to a concrete structure, by the pipe pulling on the structure as it sinks with the settling ground. Click here for a more detailed presentation on settlement loadings.

Unlike DI, PE will not naturally form a leak-free seal when embedded into the concrete. PE expands when surrounded by mass concrete, due to the increase in temperature of curing concrete. Once the concrete cools, the PE reverts to its original size leaving a small gap between the PE and the concrete, this gap allows water to pass both into or out of the structure.

To prevent this a Hydrophilic vulcanized expansive rubber sealing ring is fitted to a groove in the puddles ring. This Hydrophilic ring expands >600% when activated by exposure to moisture. Hydrophilic sealing rings comply with ASTM D471 and must be kept dry in until they are installed and are supplied as standard.

NOTE: This product is not suitable for making pressure connections such as the base of a reservoir. Hydrophilic sealing rings are a water stop, not a pressure seal. They are designed to expand into the surrounding structure and provide a barrier to groundwater ingress or egress typically found in chambers or structures, a few meters below ground level.

| Larger sizes can be found in our Wastewater sections. | ||||||||||

| AoR dimensions are available on request, please contact us. | ||||||||||

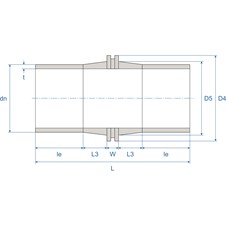

| non-Waterstop | with Waterstop | dn | t | W | D5 | D4 | L3 | le | L | Availability in Hong Kong |

| P5316.138.125 | P5316.938.125 | 125 | 11.4 | 20 | AoR | 157 | 50 | 150 | 420 | 6-8 weeks |

| P5316.138.180 | P5316.938.180 | 180 | 16.4 | 21 | AoR | 225 | 50 | 150 | 421 | 6-8 weeks |

| P5316.138.250 | P5316.938.250 | 250 | 22.7 | 29 | AoR | 313 | 50 | 250 | 629 | 6-8 weeks |

| P5316.138.315 | P5316.938.315 | 315 | 28.6 | 36 | AoR | 394 | 50 | 300 | 736 | 6-8 weeks |

| P5316.138.355 | P5316.938.355 | 355 | 32.2 | 41 | AoR | 444 | 82 | 300 | 805 | 6-8 weeks |

| P5316.138.450 | P5316.938.450 | 450 | 40.9 | 52 | AoR | 563 | 104 | 300 | 860 | 6-8 weeks |

| P5316.138.500 | P5316.938.500 | 500 | 45.4 | 57 | AoR | 625 | 114 | 350 | 985 | 6-8 weeks |

| P5316.138.560 | P5316.938.560 | 560 | 50.8 | 64 | AoR | 700 | 128 | 350 | 1020 | 6-8 weeks |

| P5316.138.630 | P5316.938.630 | 630 | 57.2 | 72 | AoR | 788 | 144 | 350 | 1060 | 6-8 weeks |

| P5316.138.710 | P5316.938.710 | 710 | 64.5 | 81 | AoR | 888 | 162 | 350 | 1105 | 6-8 weeks |

| P5316.138.800 | P5316.938.800 | 800 | 72.6 | 91 | AoR | 1000 | 182 | 350 | 1155 | 6-8 weeks |

Puddle Flange / Butt Fusion / PN10 / SDR17 / with optional Waterstop

As above, however, machined to suit SDR 17 pipes with butt fusion ends for site butt welding.

| Above dn800, puddle flanges are supplied with fusion weld ends for factory joining to a pipe to reduce site welds. Long spigots versions are available on request. | ||||||||||

| Other sizes and SDRs are available on request, please contact us. | ||||||||||

| AoR dimensions are available on request, please contact us. | ||||||||||

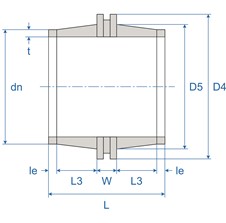

| non-Waterstop | with Waterstop | dn | t | W | D5 | D4 | L3 | le | L | Availability in Hong Kong |

| P2314.138.900 | P2314.938.900 | 900 | 53.3 | 67 | AoR | 1045 | 134 | 100 | 535 | 6-8 weeks |

| P2314.138.1000 | P2314.938.1000 | 1000 | 59.3 | 74 | AoR | 1161 | 148 | 100 | 570 | 6-8 weeks |

| P2314.138.1200 | P2314.938.1200 | 1200 | 71.1 | 89 | AoR | 1393 | 178 | 100 | 645 | 6-8 weeks |