Specialty Bends

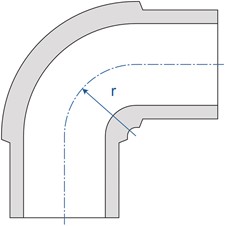

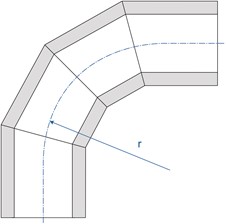

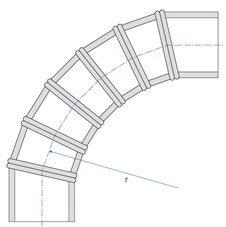

Elbows are bends with a very tight Radius, typically r=0.5x OD. Elbows allow changes in direction using minimal space. Injection moulded elbows have external reinforcement built into the design and are available in sizes up to dn630. Typically in sizes above dn355, segmented bends are used in wastewater as they are more readily available in small quantities. These are fabricated from pipe sections cut on a ≤ 7.5º angle and butt welded into one or more mitre joints ≤15º. Segmented bends cannot be manufactured with a tight radius, as space is required between each segment for the butt weld and to grip the pipe during fabrication. Typical radii are r=2.5xOD however, tighter radii segmented bends can be achieved if 15º cut angles are used. This means fabricating the bends using 3 x 30º mitre joint rather than 6 x 15º, however, 15º cut angle bends must be made from thicker pipe, in order to provide the external reinforcement or be pressure de-rated as required in BS EN 12201-3 Annex B Table B3.

-

Injection moulded elbow, reinforcement is moulded into the fitting, radius r=0.5xOD

-

Segmented bends with 15º cut angle and 3x 30º mitres, r=1.5xOD. Manufactured from thicker pipe, 1xPN rating higher, to avoid 20% de-ration.

-

Segmented bends with a cut angle ≤ 7.5º ( 6x 15º mitres) r=2.5xOD. No de-ration required, however the radius is large.

Fabricated Elbows

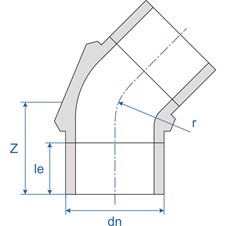

Where there is insufficient space to install large radius segmented bends, fabricated elbows can be used. Similar to Fabricated tees, fabricated elbows are created by machining a curved fitting body from extruded hollow bar. Reinforcement is included during machining and any angle from 1º to 45º can be created. Spigots are factory butt-welded to the fitting body to create a fabricated elbow with a radius of r=0.5xOD. No de-ration is required, as the reinforcement is included as part of the fitting design.

For angles greater than 45º, two fittings bodies that sum to the required angle (eg: 2x45º fabricated elbows = 90º) are factory butt welded together. Using this method any angle from 1º to 90º can be manufactured with a radius of r=~0.5xOD. These bends are ideal for the installation of bends on large diameter pipes (≥ dn355), in tight construction environments found in Hong Kong, where there is insufficient space to install segmented bends. See some examples of Reinert Ritz fabricated compact short radius elbows in use below in both 90º and various custom angles below.

Fabricated elbows come standard in 45º. Elbows up to 90º are manufactured by factory butt welding two 45º elbows together. Fabricated elbows are machined from black PE100+ compound in PN10 SDR17 and PN16 SDR11 ratings. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Fabricated elbows have a radius of r=~0.5xOD.

Black 11º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

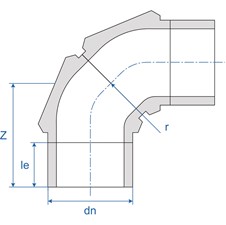

Fabricated elbows are designed for applications where there is insufficient space for segmented bends to be used. Manufactured from black PE100+ compound, they feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below show standard 11º elbow with a radius of ~0.5xOD.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

|

PN10 SDR17 |

PN16 SDR11 | d1 | le1 | r | z1 - 11º | Availability in Hong Kong |

| P5314.76.355 | P5316.76.355 | 355 | 200 | 177 | 309 | 14-16 weeks |

| P5314.76.400 | P5316.76.400 | 400 | 300 | 200 | 411 | 14-16 weeks |

| P5314.76.450 | P5316.76.450 | 450 | 300 | 225 | 413 | 14-16 weeks |

| P5314.76.500 | P5316.76.500 | 500 | 300 | 250 | 426 | 14-16 weeks |

| P5314.76.560 | P5316.76.560 | 560 | 300 | 280 | 451 | 14-16 weeks |

| P5314.76.630 | P5316.76.630 | 630 | 300 | 315 | 460 | 14-16 weeks |

| P5314.76.710 | P5316.76.710 | 710 | 500 | 355 | 662 | 14-16 weeks |

| P5314.76.800 | P5316.76.800 | 800 | 500 | 400 | 663 | 14-16 weeks |

| P5314.76.900 | P5316.76.900 | 900 | 500 | 450 | 732 | 14-16 weeks |

| P5314.76.1000 | P5316.76.1000 | 1000 | 500 | 500 | 741 | 14-16 weeks |

| P5314.76.1200 | - | 1200 | 500 | 600 | 709 | 14-16 weeks |

| P5314.76.1400 | - | 1400 | 500 | 700 | 777 | 14-16 weeks |

Black 22º Fabricated spigot elbows PN10-PN16 / SDR17-SDR11

Fabricated elbows are designed for applications where there is insufficient space for segmented bends to be used. Manufactured from black PE100+ compound, they feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below show standard 22º elbow with a radius of ~0.5xOD.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | d1 | le1 | r | z1 - 22º | Availability in Hong Kong |

| P5314.77.355 | P5316.77.355 | 355 | 200 | 177 | 326 | 14-16 weeks |

| P5314.77.400 | P5316.77.400 | 400 | 300 | 200 | 431 | 14-16 weeks |

| P5314.77.450 | P5316.77.450 | 450 | 300 | 225 | 436 | 14-16 weeks |

| P5314.77.500 | P5316.77.500 | 500 | 300 | 250 | 450 | 14-16 weeks |

| P5314.77.560 | P5316.77.560 | 560 | 300 | 280 | 478 | 14-16 weeks |

| P5314.77.630 | P5316.77.630 | 630 | 300 | 315 | 491 | 14-16 weeks |

| P5314.77.710 | P5316.77.710 | 710 | 500 | 355 | 697 | 14-16 weeks |

| P5314.77.800 | P5316.77.800 | 800 | 500 | 400 | 702 | 14-16 weeks |

| P5314.77.900 | P5316.77.900 | 900 | 500 | 450 | 776 | 14-16 weeks |

| P5314.77.1000 | P5316.77.1000 | 1000 | 500 | 500 | 790 | 14-16 weeks |

| P5314.77.1200 | - | 1200 | 500 | 600 | 768 | 14-16 weeks |

| P5314.77.1400 | - | 1400 | 500 | 700 | 846 | 14-16 weeks |

Black 30º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated elbows have a fitting body that is machined from black PE100+ hollow bar with the required reinforcement included in the design. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 90º can be manufactured. Tables below show standard 30º elbow with a radius of ~0.5xOD for reference.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | dn | le | r | z - 30º | Availability in Hong Kong |

| P5314.78.355 | P5316.78.355 | 355 | 200 | 177 | 339 | 14-16 weeks |

| P5314.78.400 | P5316.78.400 | 400 | 300 | 200 | 446 | 14-16 weeks |

| P5314.78.450 | P5316.78.450 | 450 | 300 | 225 | 452 | 14-16 weeks |

| P5314.78.500 | P5316.78.500 | 500 | 300 | 250 | 468 | 14-16 weeks |

| P5314.78.560 | P5316.78.560 | 560 | 300 | 280 | 499 | 14-16 weeks |

| P5314.78.630 | P5316.78.630 | 630 | 300 | 315 | 514 | 14-16 weeks |

| P5314.78.710 | P5316.78.710 | 710 | 500 | 355 | 723 | 14-16 weeks |

| P5314.78.800 | P5316.78.800 | 800 | 500 | 400 | 731 | 14-16 weeks |

| P5314.78.900 | P5316.78.900 | 900 | 500 | 450 | 809 | 14-16 weeks |

| P5314.78.1000 | P5316.78.1000 | 1000 | 500 | 500 | 827 | 14-16 weeks |

| P5314.78.1200 | - | 1200 | 500 | 600 | 812 | 14-16 weeks |

| P5314.78.1400 | - | 1400 | 500 | 700 | 898 | 14-16 weeks |

Black 45º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated elbows are manufactured from black PE100+ compound. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below show standard 45º elbow with a radius of ~0.5xOD for reference.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | d1 | le1 | r | z1 - 45º | Availability in Hong Kong |

| P5314.79.355 | P5316.79.355 | 355 | 200 | 177 | 365 | 14-16 weeks |

| P5314.79.400 | P5316.79.400 | 400 | 300 | 200 | 475 | 14-16 weeks |

| P5314.79.450 | P5316.79.450 | 450 | 300 | 225 | 485 | 14-16 weeks |

| P5314.79.500 | P5316.79.500 | 500 | 300 | 250 | 505 | 14-16 weeks |

| P5314.79.560 | P5316.79.560 | 560 | 300 | 280 | 540 | 14-16 weeks |

| P5314.79.630 | P5316.79.630 | 630 | 300 | 315 | 560 | 14-16 weeks |

| P5314.79.710 | P5316.79.710 | 710 | 500 | 355 | 775 | 14-16 weeks |

| P5314.79.800 | P5316.79.800 | 800 | 500 | 400 | 790 | 14-16 weeks |

| P5314.79.900 | P5316.79.900 | 900 | 500 | 450 | 875 | 14-16 weeks |

| P5314.79.1000 | P5316.79.1000 | 1000 | 500 | 500 | 900 | 14-16 weeks |

| P5314.79.1200 | - | 1200 | 500 | 600 | 900 | 14-16 weeks |

| P5314.79.1400 | - | 1400 | 500 | 700 | 1000 | 14-16 weeks |

Black 60º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated elbows are manufactured from black PE100+ compound. They are manufactured by factory butt welding two 30º fabricated elbows together. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 90º can be manufactured. Tables below shows dimensions for two 30º elbows factory butt welded together to give a 60º elbow with a radius of ~0.5xOD.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | dn | le | r | z - 60º | Availability in Hong Kong |

| P5314.80.355 | P5316.80.355 | 355 | 200 | 177 | 485 | 14-16 weeks |

| P5314.80.400 | P5316.80.400 | 400 | 300 | 200 | 600 | 14-16 weeks |

| P5314.80.450 | P5316.80.450 | 450 | 300 | 225 | 614 | 14-16 weeks |

| P5314.80.500 | P5316.80.500 | 500 | 300 | 250 | 647 | 14-16 weeks |

| P5314.80.560 | P5316.80.560 | 560 | 300 | 280 | 710 | 14-16 weeks |

| P5314.80.630 | P5316.80.630 | 630 | 300 | 315 | 741 | 14-16 weeks |

| P5314.80.710 | P5316.80.710 | 710 | 500 | 355 | 961 | 14-16 weeks |

| P5314.80.800 | P5316.80.800 | 800 | 500 | 400 | 980 | 14-16 weeks |

| P5314.80.900 | P5316.80.900 | 900 | 500 | 450 | 1137 | 14-16 weeks |

| P5314.80.1000 | P5316.80.1000 | 1000 | 500 | 500 | 1174 | 14-16 weeks |

| P5314.80.1200 | - | 1200 | 500 | 600 | 1149 | 14-16 weeks |

| P5314.80.1400 | - | 1400 | 500 | 700 | 1324 | 14-16 weeks |

Black 90º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated 90º elbows are manufactured by factory butt welding two 45º elbows together. Elbows are machined from black PE100+ compound. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below shows dimensions for two 45º elbows factory butt welded together to give a 90º elbow with a radius of ~0.5xOD.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | d1 | le1 | r | z1 - 90º | Availability in Hong Kong |

| P5314.81.355 | P5316.81.355 | 355 | 200 | 177 | 560 | 14-16 weeks |

| P5314.81.400 | P5316.81.400 | 400 | 300 | 200 | 684 | 14-16 weeks |

| P5314.81.450 | P5316.81.450 | 450 | 300 | 225 | 709 | 14-16 weeks |

| P5314.81.500 | P5316.81.500 | 500 | 300 | 250 | 753 | 14-16 weeks |

| P5314.81.560 | P5316.81.560 | 560 | 300 | 280 | 828 | 14-16 weeks |

| P5314.81.630 | P5316.81.630 | 630 | 300 | 315 | 874 | 14-16 weeks |

| P5314.81.710 | P5316.81.710 | 710 | 500 | 355 | 1111 | 14-16 weeks |

| P5314.81.800 | P5316.81.800 | 800 | 500 | 400 | 1149 | 14-16 weeks |

| P5314.81.900 | P5316.81.900 | 900 | 500 | 450 | 1327 | 14-16 weeks |

| P5314.81.1000 | P5316.81.1000 | 1000 | 500 | 500 | 1386 | 14-16 weeks |

| P5314.81.1200 | - | 1200 | 500 | 600 | 1403 | 14-16 weeks |

| P5314.81.1400 | - | 1400 | 500 | 700 | 1620 | 14-16 weeks |