Air Entrapment Tee

Technical Background

In sewer rising mains (especially sizes >DN350) 'Air Entrapment Tees' are typically installed, instead of air valves mounted directly on the pipeline. Air Entrapment Tees comprises of a PE tee piece (typically an Equal tee or one size smaller) installed in the pipeline and fitted with a 316 stainless steel flanged blanking plate. This blanking plate includes a threaded or flanged SS fitting welded to the blanking plate to plumb the takeoff using PE to another location for remote air management.

The three main reasons an Air Entrapment Tee is used:

1. Insufficient cover - as the pipe size gets larger, the height from the top of the pipe to the top of the air valve increases because the components get larger. Therefore the pipeline must be buried deeper (have more cover) to accommodate the increasing air valve height inside the chamber. (The cost of burying a pipe deeper is incredibly more expensive than simply installing air valves above ground in a remote chamber away from the pipe)

2. Air valve size - Typical sewer air valves are DN 50, 80, 100, sizes greater than this are available, but are costly and not commonly available. So in larger pipelines, where large volumes of air are released when filling the pipeline, or air let in when draining the pipeline, a manifold of smaller valves is typically used.

2. Capturing air bubbles - in order to De-gas a pumped rising main effectively, you need to capture small air bubbles that are created by changes in pressure and pumping which are carried along inside the pipe. Where sewer velocities are high (>1.0m/s), especially in larger pipes, these bubbles rush past off takes quickly so are not expelled. Air Entrapment tees provide a circular 'catchment area' above the flow path to maximise capture of air bubbles created through pumping operations or changes in pressure where velocities are relatively high

This assembly also provides an access and inspection point which can also be used to launch and retrieve CCTV equipment from. These tees and blanking plates are fully pressure rated.

-

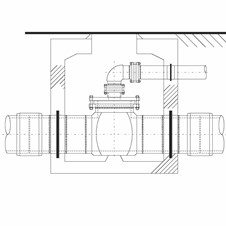

630 OD Air Entrapment Tee with 225 OD off take to 'remote' Air valve chamber

-

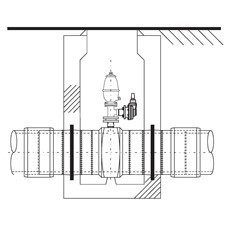

630 OD pipe with direct mounted Air Valve Tee (Typically excessively high, cannot be used)

-

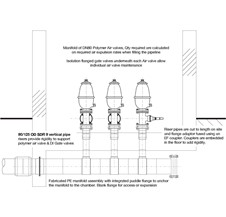

Typical remote Air Valve chamber example, Manifold of DN80 Polymer Air valves

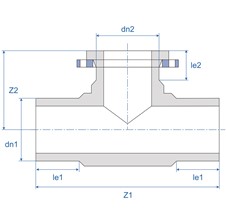

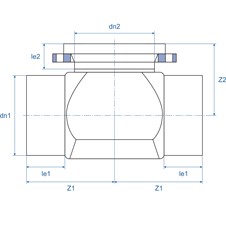

Moulded Air Tee Assembly / LS / 316SS / Flanged Branch

Fully pressure rated PE100+ fabricated assembly with long spigot ends for electrofusion on-site. Matched with a 316 Stainless Steel flanged blanking plate and a flanged or threaded reducing outlet for connection to the PE assembly with an O-Ring NBR seal. This fitting can be used for the direct connection of a sewer air valve onto the pipeline or attached to PE flange adaptor and 90º bend, allowing one or more air valves to be located in an alternate location on an air release/intake manifold.

The matching grade 316 Stainless steel flanged plate resists H2SO4 attack and provides a maintenance-free performance equivalent to the life of the PE pipe. The flange offtake size is configurable in various combinations to suit the application - Refer to the flange blanking plate table below.

| Z2 (height of off take flange) is shown as '≥ XXX' meaning this product can be custom ordered with a Z2 dimension equal to or greater than that given in this table. | |||||||

| This assembly is combined with a 316SS flanged blanking plate selected from the table below. Includes seal and 316 (A4) stainless fastenings. | |||||||

| For smaller sizes, use EF Tee, and LS flange assembly. | |||||||

| PN10 SDR17 | PN16 SDR11 | dn1 | dn2 | Z1 | le | Z2 | Availability in Hong Kong |

| P5314.C6.250250 | P5316.C6.250250 | 250 | 250 FL 250 PN16 | 535 | 130 | ≥ 273 | 8-12 weeks |

| P5314.C6.280250 | P5316.C6.280250 | 280 | 280 FL 250 PN16 | 602 | 139 | ≥ 292 | 8-12 weeks |

| P5314.C6.315300 | P5316.C6.315300 | 315 | 315 FL 300 PN16 | 650 | 150 | ≥ 317 | 8-12 weeks |

| P5314.C6.355350 | P5316.C6.355350 | 355 | 355 FL 350 PN16 | 722 | 168 | ≥ 376 | 8-12 weeks |

| P5314.C6.400400 | P5316.C6.400400 | 400 | 400 FL 400 PN16 | 728 | 145 | ≥ 408 | 8-12 weeks |

| P5314.C6.450450 | P5316.C6.450450 | 450 | 450 FL 450 PN16 | 890 | 195 | ≥ 443 | 8-12 weeks |

| P5314.C6.500500 | Select from the table below | 500 | 500 FL 500 PN16 | 1036 | 230 | ≥ 489 | 8-12 weeks |

| P5314.C6.560500 | Select from the table below | 560 | 560 FL 500 PN16 | 1085 | 230 | ≥ 541 | 8-12 weeks |

| P5314.C6.630600 | Select from the table below | 630 | 630 FL 600 PN16 | 1175 | 230 | ≥ 586 | 8-12 weeks |

Reinforced Air Tee Assembly / LS / 316SS / Flanged Branch

As above using fabricated PE tees offering PN16 pressure ratings in larger sizes.

| SDR17 PN10 | SDR11 PN16 | dn1 | DN | L | le | Z1 | Z2 | Availability in Hong Kong |

| The above assembly is combined with a 316SS flanged blanking plate selected from the table below. Includes seal and 316 (A4) stainless fastenings. | ||||||||

| Larger sizes in SDR17 / PN10 available to DN1800. | ||||||||

| This assembly is combined with a 316SS flanged blanking plate selected from the table below. Includes seal and 316 (A4) stainless fastenings. | ||||||||

| For smaller sizes, use EF Tee, and LS flange assembly. | ||||||||

| P5314.61.250250 | P5316.61.250250 | 250 | 250 FL DN250 PN16 | 830 | 250 | 415 | 273 | 8-12 weeks |

| P5314.61.280250 | P5316.61.280250 | 280 | 280 FL DN250 PN16 | 690 | 250 | 345 | 292 | 8-12 weeks |

| P5314.61.315300 | P5316.61.315300 | 315 | 315 FL DN300 PN16 | 1005 | 300 | 503 | 317 | 8-12 weeks |

| P5314.61.355350 | P5316.61.355350 | 355 | 355 FL DN350 PN16 | 1045 | 300 | 523 | 376 | 8-12 weeks |

| P5314.61.400400 | P5316.61.400400 | 400 | 400 FL DN400 PN16 | 1100 | 300 | 550 | 408 | 8-12 weeks |

| P5314.61.450450 | P5316.61.450450 | 450 | 450 FL DN450 PN16 | 1160 | 300 | 580 | 443 | 8-12 weeks |

| P5314.61.500500 | P5316.61.500500 | 500 | 500 FL DN500 PN16 | 1310 | 350 | 655 | 489 | 8-12 weeks |

| P5314.61.560500 | P5316.61.560500 | 560 | 560 FL DN500 PN16 | 1380 | 350 | 690 | 541 | 8-12 weeks |

| P5314.61.630600 | P5316.61.630600 | 630 | 630 FL DN600 PN16 | 1450 | 350 | 725 | 586 | 8-12 weeks |

| P5314.61.710700 | P5316.61.710700 | 710 | 710 FL DN700 PN16 | 1530 | 350 | 765 | 675 | 8-12 weeks |

| P5314.61.800800 | P5316.61.800800 | 800 | 800 FL DN800 PN16 | 1660 | 350 | 830 | 743 | 8-12 weeks |

| P5314.61.900900 | P5316.61.900900 | 900 | 900 FL DN900 PN16 | 1860 | 400 | 930 | 815 | 8-12 weeks |

| P5314.61.10001000 | P5316.61.10001000 | 1000 | 1000 FL DN1000 PN16 | 1960 | 400 | 980 | 886 | 8-12 weeks |

| P5314.61.12001200 | - | 1200 | 1200 FL DN1200 PN16 | 2170 | 400 | 1085 | 1044 | 8-12 weeks |

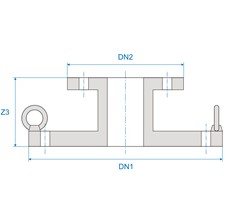

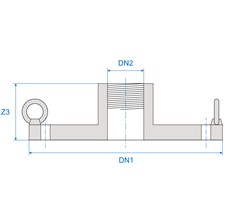

Air Tee Double Flanged Spool / PN16 / 316SS

Fabricated from 316 Stainless steel complying to BS EN 10088-2 Grade 1.4401 or 1.4404. Both flanges are BS EN 1092-1 rated and drilled PN16 unless indicated as a 'BSP' threaded SS socket for DN 50 offtakes. All Flanges supplied with SS lifting hooks blind threaded into the flange.

| The blanking flange is fabricated to order so any combination of flange and off-take is available, typical combinations are shown above. | ||||

| Product Code | DN1 (Blanking Flange) |

DN2 (off-take) Flanged unless stated as BSP |

Z3 | Availability in Hong Kong |

| P09S6.557.10088 | 100 | 50 BSP | 102 | 8-12 Weeks |

| P09S6.G6.100080 | 100 | 80 | 107 | 8-12 Weeks |

| P09S6.557.15088 | 150 | 50 BSP | 104 | 8-12 Weeks |

| P09S6.G6.150080 | 150 | 80 | 109 | 8-12 Weeks |

| P09S6.G6.150100 | 150 | 100 | 121 | 8-12 Weeks |

| P09S6.557.20088 | 200 | 50 BSP | 106 | 8-12 Weeks |

| P09S6.G6.200080 | 200 | 80 | 111 | 8-12 Weeks |

| P09S6.G6.200100 | 200 | 100 | 123 | 8-12 Weeks |

| P09S6.557.25088 | 250 | 50 BSP | 109 | 8-12 Weeks |

| P09S6.G6.250080 | 250 | 80 | 114 | 8-12 Weeks |

| P09S6.G6.250100 | 250 | 100 | 126 | 8-12 Weeks |

| P09S6.557.30088 | 300 | 50 BSP | 112 | 8-12 Weeks |

| P09S6.G6.300080 | 300 | 80 | 117 | 8-12 Weeks |

| P09S6.G6.300100 | 300 | 100 | 129 | 8-12 Weeks |

| P09S6.557.35088 | 350 | 50 BSP | 115 | 8-12 Weeks |

| P09S6.G6.350080 | 350 | 80 | 120 | 8-12 Weeks |

| P09S6.G6.350100 | 350 | 100 | 132 | 8-12 Weeks |

| P09S6.557.40088 | 400 | 50 BSP | 120 | 8-12 Weeks |

| P09S6.G6.400080 | 400 | 80 | 125 | 8-12 Weeks |

| P09S6.G6.400100 | 400 | 100 | 137 | 8-12 Weeks |

| P09S6.557.45088 | 450 | 50 BSP | 122 | 8-12 Weeks |

| P09S6.G6.450080 | 450 | 80 | 127 | 8-12 Weeks |

| P09S6.G6.450100 | 450 | 100 | 139 | 8-12 Weeks |

| P09S6.557.50088 | 500 | 50 BSP | 126 | 8-12 Weeks |

| P09S6.G6.500080 | 500 | 80 | 131 | 8-12 Weeks |

| P09S6.G6.500100 | 500 | 100 | 143 | 8-12 Weeks |

| P09S6.G6.600080 | 600 | 80 | 140 | 8-12 Weeks |

| P09S6.G6.600100 | 600 | 100 | 152 | 8-12 Weeks |

| P09S6.G6.710080 | 710 | 80 | 148 | 8-12 Weeks |

| P09S6.G6.710100 | 710 | 100 | 160 | 8-12 Weeks |

| P09S6.G6.710150 | 710 | 150 | 187 | 8-12 Weeks |

| P09S6.G6.800080 | 800 | 80 | 159 | 8-12 Weeks |

| P09S6.G6.800100 | 800 | 100 | 171 | 8-12 Weeks |

| P09S6.G6.800150 | 800 | 150 | 198 | 8-12 Weeks |

| P09S6.G6.800200 | 800 | 200 | 210 | 8-12 Weeks |

| P09S6.G6.900080 | 900 | 80 | 167 | 8-12 Weeks |

| P09S6.G6.900100 | 900 | 100 | 179 | 8-12 Weeks |

| P09S6.G6.900150 | 900 | 150 | 206 | 8-12 Weeks |

| P09S6.G6.900200 | 900 | 200 | 218 | 8-12 Weeks |

| P09S6.G6.1000080 | 1000 | 80 | 175 | 8-12 Weeks |

| P09S6.G6.1000100 | 1000 | 100 | 187 | 8-12 Weeks |

| P09S6.G6.1000150 | 1000 | 150 | 214 | 8-12 Weeks |

| P09S6.G6.1000200 | 1000 | 200 | 226 | 8-12 Weeks |

| P09S6.G6.1000250 | 1000 | 250 | 239 | 8-12 Weeks |

| P09S6.G6.1200080 | 1200 | 80 | 185 | 8-12 Weeks |

| P09S6.G6.1200100 | 1200 | 100 | 197 | 8-12 Weeks |

| P09S6.G6.1200150 | 1200 | 150 | 224 | 8-12 Weeks |

| P09S6.G6.1200200 | 1200 | 200 | 236 | 8-12 Weeks |

| P09S6.G6.1200250 | 1200 | 250 | 249 | 8-12 Weeks |

| P09S6.G6.1200300 | 1200 | 300 | 262 | 8-12 Weeks |