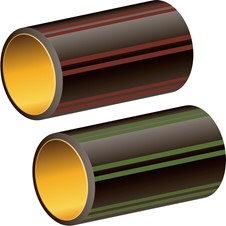

M90SE Co-Extruded Striped Pipes

M90SE Brown Twin Stripe / PN10 / SDR17 / Sewer pipes

M90SE Pipe – Two colour PE100 RC pipes, manufactured to BS EN 12201-2, with a 15% inner CCTV inspection assistance layer. Pairs of Red Brown striping, indicating a pressure Sewer application. Pipes are extruded using the same PE100 RC base compounds for the pipe body, inner CCTV colour and indication striping. This ensures a single homogeneous pipe is extruded, eliminating electrofusion leak issues associated with using non PE100 RC striping compounds.

M90S Pipes – Manufactured from PE100+ compound (Not using PE100 RC) are only manufactured by special order to the same dimensions given below.

INDICATION STRIPING – Pairs of PE100 RC Red Brown (RAL 8012) coloured stripes, indicating pressure Sewer.

| Product code | DSD Equivalent Size | Nominal Outside Diameter (dn) | Mean Outside Diameter dem | Maximum Out-of-roundness | SDR 17 | Availability in Hong Kong | |||

| Wall (em) | ID | Kg/m | |||||||

| DN | DN/OD | Min. | Max. | (ovality) | Mean | Mean | Mean | ||

| P1Q54.102.110 | DN 100 | 110 | 110 | 110.7 | 2.2 | 7.0 | 96.4 | 2.2 | 8-12 Weeks |

| P1Q54.102.125 | Non Std Size | 125 | 125 | 125.8 | 2.5 | 7.9 | 109.7 | 2.8 | 8-12 Weeks |

| P1Q54.102.140 | Non Std Size | 140 | 140 | 140.9 | 2.8 | 8.8 | 122.9 | 3.5 | 8-12 Weeks |

| P1Q54.102.160 | DN 150 | 160 | 160 | 161.0 | 3.2 | 10.1 | 140.4 | 4.6 | 8-12 Weeks |

| P1Q54.102.180 | Non Std Size | 180 | 180 | 181.1 | 3.6 | 11.3 | 158.0 | 4.6 | 8-12 Weeks |

| P1Q54.102.200 | Non Std Size | 200 | 200 | 201.2 | 4.0 | 12.6 | 175.5 | 7.1 | 8-12 Weeks |

| P1Q54.102.225 | DN 200 | 225 | 225 | 226.4 | 4.5 | 14.2 | 197.4 | 9.0 | 8-12 Weeks |

| P1Q54.102.250 | DN 225 | 250 | 250 | 251.5 | 5.0 | 15.6 | 219.6 | 11.1 | 8-12 Weeks |

| P1Q54.102.280 | DN 250 | 280 | 280 | 281.7 | 9.8 | 17.5 | 245.9 | 13.9 | 8-12 Weeks |

| P1Q54.102.315 | Non Std Size | 315 | 315 | 316.9 | 11.1 | 19.7 | 276.6 | 17.6 | 8-12 Weeks |

| P1Q54.102.355 | DN 300 | 355 | 355 | 357.2 | 12.5 | 22.3 | 311.6 | 22.4 | 8-12 Weeks |

| P1Q54.102.400 | DN 375 | 400 | 400 | 402.4 | 14.0 | 25.0 | 351.3 | 28.3 | 8-12 Weeks |

| P1Q54.102.450 | DN 400 | 450 | 450 | 452.7 | 15.6 | 28.1 | 395.2 | 35.8 | 8-12 Weeks |

| P1Q54.102.500 | DN 450 | 500 | 500 | 503.0 | 17.5 | 31.2 | 439.2 | 44.2 | 8-12 Weeks |

| P1Q54.102.560 | DN 500 | 560 | 560 | 563.4 | 19.6 | 35.0 | 491.8 | 55.5 | 8-12 Weeks |

| P1Q54.102.630 | DN 525 | 630 | 630 | 633.8 | 22.1 | 39.3 | 553.4 | 70.1 | 8-12 Weeks |

| P1Q54.102.710 | DN 600 | 710 | 710 | 716.4 | 24.9 | 44.3 | 624.6 | 89.3 | 8-12 Weeks |

| P1Q54.102.800 | DN 675 | 800 | 800 | 807.2 | 28.0 | 49.9 | 703.9 | 113.2 | 8-12 Weeks |

| P1Q54.102.900 | DN 825 | 900 | 900 | 908.1 | 31.5 | 56.3 | 791.6 | 143.7 | Contact us |

| P1Q54.102.1000 | DN 900 | 1000 | 1000 | 1009.0 | 35.0 | 62.4 | 879.8 | 177.1 | Contact us |

| P1Q54.102.1200 | DN 1050 | 1200 | 1200 | 1210.8 | 42.0 | 74.2 | 1057.1 | 252.8 | Contact us |

| P1Q54.102.1400 | DN 1200 | 1400 | 1400 | 1412.6 | 49.0 | 86.6 | 1233.2 | 344.3 | Contact us |

| P1Q54.102.1600 | DN 1350 | 1600 | 1600 | 1614.4 | 56.0 | 98.9 | 1409.4 | 449.6 | Contact us |

Note:

1. Non Std Size are sizes that are not listed in the DSD Appendix 5A conversion tables. These sizes are typically only required when matching the PE pipe to an existing pump curve. These sizes are not stocked and subject to Minimum Order Quantities (Approx 400m), Contact us for more information.

2. Pressure Sewer pipes are not alwasy stocked, orders maybe subject to Minimum Order Quantities (approx 400m), Contact us for more information.

2. All pipes listed with product codes are supplied in straight 5.80m lengths, Contact us for custom lengths up to 11.8m.

M90SE Green Twin Stripe / PN10 / SDR17 / Stormwater pipe

M90SE Pipe – Two-colour PE100 RC pipes, manufactured to BS EN 12201-2, with a 15% inner CCTV inspection assistance layer. Pairs of Fern green striping, indicating a pressure Stormwater application. Pipes are extruded using the same PE100 RC base compounds for the pipe body, inner CCTV colour and indication striping. This ensures a single homogeneous pipe is extruded, eliminating electrofusion leak issues associated with using non-PE100 RC striping compounds.

M90S Pipes – Manufactured from PE100+ compound (Not using PE100 RC) are only manufactured by special order to the same dimensions given below.

INDICATION STRIPING – Pairs of PE100 RC Fern Green (RAL 6025) coloured stripes indicating pressure Stormwater.

| Product code | DSD Equivalent Size | Nominal Outside Diameter (dn) | Mean Outside Diameter dem | Maximum Out-of-roundness | SDR 17 | Availability in Hong Kong | |||

| Wall (em) | ID | Kg/m | |||||||

| DN | DN/OD | Min. | Max. | (ovality) | Mean | Mean | Mean | ||

| P1QG4.102.110 | DN 100 | 110 | 110 | 110.7 | 2.2 | 7.0 | 96.4 | 2.2 | 8-12 Weeks |

| P1QG4.102.125 | Non Std Size | 125 | 125 | 125.8 | 2.5 | 7.9 | 109.7 | 2.8 | 8-12 Weeks |

| P1QG4.102.140 | Non Std Size | 140 | 140 | 140.9 | 2.8 | 8.8 | 122.9 | 3.5 | 8-12 Weeks |

| P1QG4.102.160 | DN 150 | 160 | 160 | 161.0 | 3.2 | 10.1 | 140.4 | 4.6 | 8-12 Weeks |

| P1QG4.102.180 | Non Std Size | 180 | 180 | 181.1 | 3.6 | 11.3 | 158.0 | 4.6 | 8-12 Weeks |

| P1QG4.102.200 | Non Std Size | 200 | 200 | 201.2 | 4.0 | 12.6 | 175.5 | 7.1 | 8-12 Weeks |

| P1QG4.102.225 | DN 200 | 225 | 225 | 226.4 | 4.5 | 14.2 | 197.4 | 9.0 | 8-12 Weeks |

| P1QG4.102.250 | DN 225 | 250 | 250 | 251.5 | 5.0 | 15.6 | 219.6 | 11.1 | 8-12 Weeks |

| P1QG4.102.280 | DN 250 | 280 | 280 | 281.7 | 9.8 | 17.5 | 245.9 | 13.9 | 8-12 Weeks |

| P1QG4.102.315 | Non Std Size | 315 | 315 | 316.9 | 11.1 | 19.7 | 276.6 | 17.6 | 8-12 Weeks |

| P1QG4.102.355 | DN 300 | 355 | 355 | 357.2 | 12.5 | 22.3 | 311.6 | 22.4 | 8-12 Weeks |

| P1QG4.102.400 | DN 375 | 400 | 400 | 402.4 | 14.0 | 25.0 | 351.3 | 28.3 | 8-12 Weeks |

| P1QG4.102.450 | DN 400 | 450 | 450 | 452.7 | 15.6 | 28.1 | 395.2 | 35.8 | 8-12 Weeks |

| P1QG4.102.500 | DN 450 | 500 | 500 | 503.0 | 17.5 | 31.2 | 439.2 | 44.2 | 8-12 Weeks |

| P1QG4.102.560 | DN 500 | 560 | 560 | 563.4 | 19.6 | 35.0 | 491.8 | 55.5 | 8-12 Weeks |

| P1QG4.102.630 | DN 525 | 630 | 630 | 633.8 | 22.1 | 39.3 | 553.4 | 70.1 | 8-12 Weeks |

| P1QG4.102.710 | DN 600 | 710 | 710 | 716.4 | 24.9 | 44.3 | 624.6 | 89.3 | 8-12 Weeks |

| P1QG4.102.800 | DN 675 | 800 | 800 | 807.2 | 28.0 | 49.9 | 703.9 | 113.2 | 8-12 Weeks |

| P1QG4.102.900 | DN 825 | 900 | 900 | 908.1 | 31.5 | 56.3 | 791.6 | 143.7 | Contact us |

| P1QG4.102.1000 | DN 900 | 1000 | 1000 | 1009.0 | 35.0 | 62.4 | 879.8 | 177.1 | Contact us |

| P1QG4.102.1200 | DN 1050 | 1200 | 1200 | 1210.8 | 42.0 | 74.2 | 1057.1 | 252.8 | Contact us |

| P1QG4.102.1400 | DN 1200 | 1400 | 1400 | 1412.6 | 49.0 | 86.6 | 1233.2 | 344.3 | Contact us |

| P1QG4.102.1600 | DN 1350 | 1600 | 1600 | 1614.4 | 56.0 | 98.9 | 1409.4 | 449.6 | Contact us |

Note:

1. Non Std Size are sizes that are not listed in the DSD Appendix 5A conversion tables. These sizes are typically only required when matching the PE pipe to an existing pump curve. These sizes are not stocked and subject to Minimum Order Quantities (Approx 400m), Contact us for more information.

2. Pressure Stormwater pipes are not common, so orders are subject to Minimum Order Quantities (approx 400m), Contact us for more information.

3. All pipes listed with product codes are supplied in straight 5.80m lengths, Contact us for custom lengths up to 11.8m.

M90SE Green / Brown Twin Stripe / Other PN / SDR Ratings

M90ES - PE100 RC Pipes available in other sizes and pressure ratings (Green or Brown Stripe)

Below is a wider range of M90ES pipe sizes and pressure ratings available from PN8 to PN25 that also comply with DSD Appendix 5A (for PN10 sizes see tables above) These pipes are manufactured using PE100 RC compounds as standard unless ordered otherwise.

In addition, non-standard pipe sizes of any OD and SDR within the ranges given below, can be manufactured for relining & rehabilitation work, contact us for more information on the supply of non-standard size relining pipes.

| Stiffness Rating PE100 | SN6 | SN12 | SN24 | SN50 | SN100 | SN195 | SN381 | ||||||||||||||||||

| Pressure Rating PE100 | PN6.4 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 | ||||||||||||||||||

| Nominal Diameter | Diameter dem | Maximum Out-of-roundness | SDR 26 | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | SDR 7.4 | ||||||||||||||||

| em | di | Kg/m | em | di | Kg/m | em | di | Kg/m | em | di | Kg/m | em | di | Kg/m | em | di | Kg/m | em | di | Kg/m | |||||

| DN | dn | Min. | Max. | (ovality) | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean | Mean |

| 90 | 90 | 90 | 90.6 | 1.8 | 3.8 | 82.8 | 1.0 | 4.6 | 81.1 | 1.2 | 5.8 | 78.8 | 1.5 | 7.1 | 76.1 | 1.8 | 8.7 | 72.9 | 2.1 | 10.7 | 68.9 | 2.6 | 13.0 | 64.3 | 3.0 |

| 100 | 110 | 110 | 110.7 | 2.2 | 4.6 | 101.2 | 1.5 | 5.7 | 99.1 | 1.8 | 7.0 | 96.4 | 2.2 | 8.6 | 93.2 | 2.6 | 10.6 | 89.3 | 3.2 | 13.0 | 84.4 | 3.8 | 16.0 | 78.5 | 4.5 |

| - | 125 | 125 | 125.8 | 2.5 | 5.1 | 115.2 | 1.8 | 6.4 | 112.7 | 2.3 | 7.9 | 109.7 | 2.8 | 9.8 | 105.9 | 3.4 | 12.1 | 101.3 | 4.1 | 14.8 | 95.9 | 4.9 | 18.1 | 89.3 | 5.8 |

| - | 140 | 140 | 140.9 | 2.8 | 5.8 | 129.0 | 2.3 | 7.1 | 126.3 | 2.9 | 8.8 | 122.9 | 3.5 | 10.9 | 118.7 | 4.3 | 13.4 | 113.7 | 5.1 | 16.6 | 107.4 | 6.2 | 20.3 | 100.0 | 7.3 |

| 150 | 160 | 160 | 161.0 | 3.2 | 6.6 | 147.3 | 3.1 | 8.2 | 144.2 | 3.7 | 10.1 | 140.4 | 4.6 | 12.5 | 135.6 | 5.6 | 15.4 | 129.7 | 6.7 | 18.9 | 122.8 | 8.0 | 23.1 | 114.4 | 9.5 |

| - | 180 | 180 | 181.1 | 3.6 | 7.3 | 166.0 | 3.8 | 9.1 | 162.4 | 4.7 | 11.3 | 158.0 | 5.8 | 14.1 | 152.5 | 7.1 | 17.3 | 146.0 | 8.5 | 21.2 | 138.2 | 10.2 | 25.9 | 128.8 | 12.1 |

| - | 200 | 200 | 201.2 | 4.0 | 8.2 | 184.3 | 4.7 | 10.2 | 180.3 | 5.8 | 12.6 | 175.5 | 7.1 | 15.5 | 169.6 | 8.6 | 19.2 | 162.2 | 10.5 | 23.6 | 153.4 | 12.6 | 28.8 | 143.1 | 14.9 |

| 200 | 225 | 225 | 226.4 | 4.5 | 9.1 | 207.5 | 5.9 | 11.4 | 202.9 | 7.4 | 14.2 | 197.4 | 9.0 | 17.5 | 190.7 | 11.0 | 21.6 | 182.5 | 13.3 | 26.5 | 172.8 | 15.9 | 32.4 | 160.9 | 18.9 |

| 225 | 250 | 250 | 251.5 | 5.0 | 10.2 | 230.5 | 7.4 | 12.6 | 225.7 | 9.0 | 15.6 | 219.6 | 11.1 | 19.4 | 212.0 | 13.5 | 23.9 | 203.0 | 16.3 | 29.4 | 192.1 | 19.6 | 36.0 | 178.8 | 23.3 |

| 250 | 280 | 280 | 281.7 | 9.8 | 11.3 | 258.3 | 9.2 | 14.2 | 252.6 | 11.4 | 17.5 | 245.9 | 13.9 | 21.7 | 237.5 | 16.9 | 26.8 | 227.4 | 20.5 | 33.0 | 215.0 | 24.6 | 40.3 | 200.3 | 29.2 |

| - | 315 | 315 | 316.9 | 11.1 | 12.8 | 290.4 | 11.7 | 15.8 | 284.4 | 14.3 | 19.7 | 276.6 | 17.6 | 24.5 | 267.1 | 21.5 | 30.1 | 255.8 | 25.9 | 37.1 | 241.9 | 31.1 | 45.2 | 225.6 | 36.9 |

| 300 | 355 | 355 | 357.2 | 12.5 | 14.4 | 327.4 | 14.8 | 17.8 | 320.5 | 18.1 | 22.3 | 311.6 | 22.4 | 27.5 | 301.1 | 27.2 | 33.9 | 288.3 | 32.9 | 41.7 | 272.8 | 39.5 | 51.0 | 254.1 | 46.9 |

| 375 | 400 | 400 | 402.4 | 14.0 | 16.2 | 368.9 | 18.7 | 20.2 | 360.9 | 23.1 | 25.0 | 351.3 | 28.3 | 31.0 | 339.3 | 34.5 | 38.2 | 324.8 | 41.8 | 47.0 | 307.2 | 50.2 | 57.4 | 286.4 | 59.5 |

| 400 | 450 | 450 | 452.7 | 15.6 | 18.2 | 415.1 | 23.7 | 22.7 | 406.1 | 29.3 | 28.1 | 395.2 | 35.8 | 34.9 | 381.7 | 43.7 | 43.0 | 365.4 | 52.9 | 52.8 | 345.8 | 63.4 | 64.7 | 322.1 | 75.4 |

| 450 | 500 | 500 | 503.0 | 17.5 | 20.2 | 461.2 | 29.2 | 25.2 | 451.2 | 36.1 | 31.2 | 439.2 | 44.2 | 38.7 | 424.1 | 54.0 | 47.8 | 406.0 | 65.3 | 58.7 | 384.2 | 78.3 | - | - | - |

| 500 | 560 | 560 | 563.4 | 19.6 | 22.6 | 516.6 | 36.6 | 28.1 | 505.5 | 45.2 | 35.0 | 491.8 | 55.5 | 43.4 | 475.0 | 67.7 | 53.4 | 454.9 | 81.8 | 65.7 | 430.3 | 98.2 | - | - | - |

| 525 | 630 | 630 | 633.8 | 22.1 | 25.4 | 581.1 | 46.4 | 31.6 | 568.8 | 57.1 | 39.3 | 553.4 | 70.1 | 48.7 | 534.5 | 85.6 | 60.2 | 511.6 | 103.7 | 73.9 | 484.1 | 124.3 | - | - | - |

| 600 | 710 | 710 | 716.4 | 24.9 | 28.7 | 655.9 | 59.1 | 35.7 | 641.9 | 72.8 | 44.3 | 624.6 | 89.3 | 54.9 | 603.4 | 108.9 | 67.8 | 577.6 | 131.9 | 83.35 | 546.5 | 158.2 | - | - | - |

| 700 | 800 | 800 | 807.2 | 28.0 | 32.2 | 739.2 | 74.9 | 40.1 | 723.4 | 92.3 | 49.9 | 703.9 | 113.2 | 61.8 | 680.0 | 138.2 | 76.3 | 651 | 167.3 | 93.85 | 615.9 | 200.8 | - | - | - |

| 800 | 900 | 900 | 908.1 | 31.5 | 36.2 | 831.7 | 94.7 | 45.1 | 813.9 | 116.8 | 56.3 | 791.6 | 143.7 | 69.6 | 764.85 | 175.0 | 85.85 | 732.35 | 211.7 | - | - | - | - | - | - |

| 900 | 1000 | 1000 | 1009.0 | 35.0 | 40.2 | 924.1 | 116.8 | 50.2 | 904.2 | 144.3 | 62.4 | 879.8 | 177.1 | 76.2 | 852.1 | 213.2 | 94.8 | 814.9 | 259.9 | - | - | - | - | - | - |

| 1000 | 1200 | 1200 | 1210.8 | 42.0 | 48.3 | 1108.9 | 168.3 | 60.2 | 1085.1 | 207.6 | 74.2 | 1057.1 | 252.8 | 92.7 | 1020 | 310.9 | - | - | - | - | - | - | - | - | - |

| 1200 | 1400 | 1400 | 1412.6 | 49.0 | 56.0 | 1294.4 | 227.7 | 70.1 | 1266.2 | 282.1 | 86.6 | 1233.2 | 344.3 | 108.1 | 1190.1 | 423.0 | - | - | - | - | - | - | - | - | - |

| 1400 | 1600 | 1600 | 1614.4 | 56.0 | 64.5 | 1478.3 | 299.7 | 80.1 | 1447.1 | 368.5 | 98.9 | 1409.4 | 449.6 | 123.55 | 1360.1 | 552.5 | - | - | - | - | - | - | - | - | - |

| 1600 | 1800 | 1800 | 1811.3 | 63.0 | 72.8 | 1660.2 | 380.0 | 89.5 | 1626.7 | 462.9 | 111.2 | 1583.4 | 567.7 | - | - | - | - | - | - | - | - | - | - | - | - |