How it works

The Odab is designed to allow the manhole to safely vent treated odourless air, whilst capturing the hydrogen sulphide from that air through absorption in a replaceable activated carbon cartridge, which can be safely disposed of at a landfill once saturated.

-

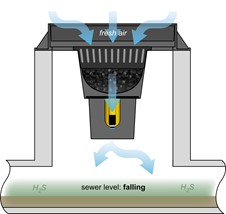

FALLING – When activity is low, sewer levels drain and fresh air is sucked into a gravity drainage system through manholes. This incoming air collapses the bellows in the Odab and exits into the sewer to fill the space left by falling sewer levels. The media is protected from surface water entering the manhole by a rainproof cap. Surface water drains into the sewer through a one way valve in the bucket of the Odab.

-

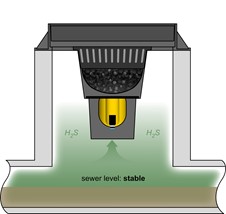

STABLE – Oxygen in the incoming air reacts with the raw sewerage, creating H2S gases in the pipeline and chamber. At this stage, there is insufficient pressure to fully inflate the bellows. The bellows expand and contract, buffering variations in the sewer levels / gas pressure. This buffering prevents the H2S gases from saturating the media.

-

RISING – As activity in the sewer increases, fluid levels rise, creating pressure for H2S to be expelled from the chamber. Once the bellows are fully expanded, further pressure of around 6 mm of water column opens the valve and the bellows ‘burps’ H2S gas into the media bed, which absorbs 95% of the H2S gas. These ‘burps’ of H2S are absorbed as the gas is forced evenly through the entire media bed and treated odourless air exits the manhole.

Treating Peak Flow

Some authorities have tried suspending an absorbing media, such as an activated carbon bed in the chamber. As soon as the chamber lid is closed, the top layer of carbon media is exposed to H2S gas continuously and is saturated in a matter of days, rendering the media and its ability to remove odour completely useless.

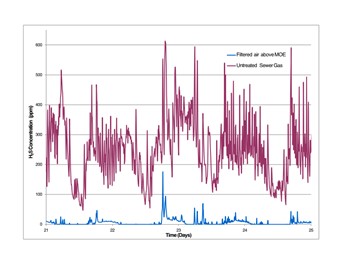

The concept of the bellows and associated valve arrangements is to ensure that ONLY peak H2S flow is treated. This concept has been well-proven in the US by multiple studies on the sister product: the Manhole Odor Eliminator MOE.

One such independent study conducted in 2012 by the University of the Pacific, Stockton California, inserted a H2S meter both above and below the pan in a chamber, measuring values at 5s intervals of H2S in the chamber above and below the manhole cover. Results over 96 hours show the effectiveness of the bellows valve system, the media bed is only exposed to approximately 1/30th of the mean average H2S in the chamber, preserving the media to only treat peak gas flows.