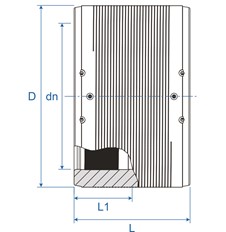

Black Couplers / EF / PN10 / SDR17

Black Couplers / AM / PN10 / SDR17

Friatec's Frialen PE100 AM black couplers are suitable for fusing pipes from SDR17 to SDR26. AM couplers feature large insertion depth for pipe stability during fusion (no holding clamps required) and extra-wide fusion and cold zones for maximum melt containment. Exposed heating coils for direct heat transmission to the pipe and a small annular gap to ensure optimum joining pressure in the fusion zone.

A visual pop up fusion indicator confirms weld pressure and traceability bar codes are included for recording batch GIS and BIM records for each coupler installed. All couplers are sealed in individual plastic bags for protection on site.

NOTE: The pipe or spigot ends and the coupler must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit for logging the full range of weld data available.

Frialen AM Electrofusion couplers are made in Germany.

| Product Code | dn | D | L | L1 | Availability in Hong Kong |

| P3314.015.110 | 110 | 130 | 160 | 80 | Ex-Stock |

| P3314.015.160 | 160 | 184 | 180 | 90 | Ex-Stock |

| P3314.015.225 | 225 | 263 | 200 | 100 | Ex-Stock |

| P3314.015.250 | 250 | 282 | 220 | 110 | Ex-Stock |

| P3314.015.280 | 280 | 316 | 220 | 110 | Ex-Stock |

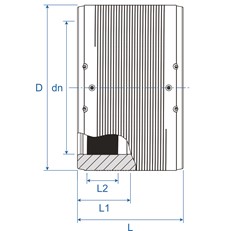

Black Couplers / UB / PN10 / SDR17

Friatec's Frialen PE100 UB17 black couplers are suitable for fusing pipes from SDR17 to SDR26. UB couplers feature large insertion depth for pipe stability during fusion (no holding clamps required) and extra-wide fusion and cold zones for maximum melt containment. Exposed heating coils for direct heat transmission to the pipe and a small annular gap to ensure optimum joining pressure in the fusion zone.

UB17 coupler sizes dn ≥ 560 include a barcode PREHEAT function to warm the pipe and coupler to help re-round oval pipes and close the fusion gap prior to welding. From dn ≥ 355 UB17's feature, permanent external reinforcement wound into the body of the coupler to ensure the coupler does not expand during the fusing process.

Note: Couplers that are not injection moulded and do not have external reinforcement are likely to expand during fusion. Coupler expansion increases the gap between the pipe and coupler, which reduces weld pressure in the joint. This leads to slow crack growth failure through the weld plane. Slow Crack Growth, by its name, is slow and occurs over time (1-5 years), well beyond the joint successfully passing hydrostatic testing on site. DSD Appendix 5A Clause 5.6.13, requires non-injection moulded couplers to have a suitable form of external reinforcement to prevent expansion applied to the coupler as parts of it's manufacture.

NOTE: The pipe or spigot ends and the coupler must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit for logging the full range of weld data available. For ≥ d1000 UB17 couplers, the Friamat XL fusion control unit must be used.

Frialen UB17 Electrofusion couplers are made in Germany.

| Product Code | dn | D | L | L1 | L2 | Availability in Hong Kong |

| P3314.100.355 | 355 | 400 | 290 | 145 | 70 | Ex-Stock |

| P3314.100.400 | 400 | 450 | 300 | 150 | 78 | Ex-Stock |

| P3314.100.450 | 450 | 506 | 320 | 160 | 87 | 8-12 Weeks |

| P3314.100.500 | 500 | 562 | 350 | 175 | 85 | Ex-Stock |

| P3314.098.560 | 560 | 630 | 380 | 190 | 77 | Ex-Stock |

| P3314.098.630 | 630 | 710 | 420 | 210 | 101 | Ex-Stock |

| P3314.098.710 | 710 | 800 | 442 | 221 | 112 | Ex-Stock |

| P3314.098.800 | 800 | 900 | 500 | 250 | 137 | Ex-Stock |

| P3314.098.900 | 900 | 1024 | 500 | 250 | 110 | 8-12 Weeks |

| P3314.098.1000 | 1000 | 1130 | 610 | 305 | 129 | 8-12 Weeks |

| P3314.098.1200 | 1200 | 1356 | 670 | 335 | 155 | 8-12 Weeks |