Hong Kong / Limitations on Reimbursement for Site Test Failures

REIMBURSEMENT LIMITATIONS FOR SITE TESTING OF POLYETHYLENE PIPES & FITTINGS

WSD Appendix 22.09 section 10, Inspection & testing after delivery / Testing and inspection / equivalent sections in other PS Appendices regarding testing of pipes and fittings after delivery-known as 'Site Testing'

Background: There have been cases of site testing of PE pipe and fittings for Hong Kong projects where the third-party testing was not conducted to a standard of integrity we would expect from an ISO/IEC 17025 certified laboratory. Due to this, we have been forced to limit our liability to pay for the retesting of failed results, where the laboratory cannot provide basic proof of a failed test or even the failed sample, therefore:

In the case of a failed pressure or Slow Crack Growth sample, where the client requests Mill-Pro to pay for retesting, the client/testing laboratory must produce the following:

- Current ISO/IEC 17025 certification that testing to EN 12201 is within their testing scope (WSD Requirement)

- Calibration certificates for the testing equipment that is not less than 12 months old (WSD requirement)

- Return of the failed sample to Hong Kong within 14 days for inspection by Mill-Pro.

- Provide Mill-Pro the test sample preparation parameters: conditioning time, actual dimensions of each v-groove cut in the pipe. (for SCG testing only)

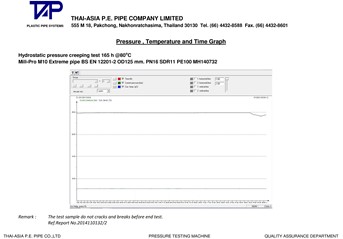

- Pressure, temperature & time data logs for the failed samples to allow us to confirm what pressures and temperatures the pipes or fittings were exposed to during testing. (an example of such a pressure/time log is provided below)

Mill-Pro stands behind every PE product we deliver; however, we cannot be held responsible for retesting of site samples where the testing lab cannot produce basic industry-standard test reporting and return the failed samples for inspection.

Example 1. Failed 165-hour @80ºC hydrostatic test. Failure was the result of a defective or uncalibrated pressure transducer which resulted in over pressurisation of the fitting during testing. The same pipe sample was retested at the same laboratory connected to a different transducer and fully complied, proving the material was not at fault. The testing laboratory was unable to provide pressure data logs of the failure or a calibration certificate for the transducer but insisted on payment for the re-test. Without the most basic documents they are required to produce under their ISO/IEC certification there is no way to confirm the accuracy of the pressure test and equipment.

Example 2. Failed 1000-hour slow crack growth test. Some laboratories offer Hong Kong contractors cheap SCG testing prices and report a failed test. They then charge the contractor to retest the pipe sample. The testing laboratory refused to return the failed sample for inspection claiming it was destroyed immediately after the test, nor could they provide copies of pressure data logs to prove they even had a failure or provide the information regarding sample preparation, conditioning and the crack dimensions. We believe this was simply a scam to recharge a second time without performing the test

For further information on recommended laboratories to use, please contact Avery Hui on +852 6110 1615