Blue 22º Bends

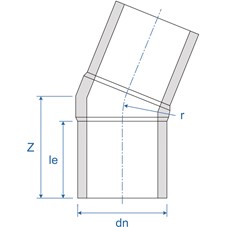

Blue 22º Injection Moulded Spigot Elbows / PN16 / SDR11

Mill-Pro PE100 RC Injection moulded spigot elbows are manufactured using Mill-Pro's own tooling under our continuous inspection. They feature long spigots for electrofusion or butt fusion joining and built-in reinforcement that exceeds the type testing requirements of BS EN 12201-2 and ISO 4427-3. Mill-Pro fittings feature hard moulded brand, batch numbers for compliance checking and 1D and 2D bar code stickers for complete product traceability. All elbows are sealed in individual plastic bags for protection on site. Spigot fittings are joined by Electrofusion Couplers or Butt Fusion.

NOTE: The pipe and spigot ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes.

|

Product Code |

dn |

le |

r |

Z |

Availability in Hong Kong |

|

P5826.110.032 |

32 |

45 |

16 |

48 |

Ex-Stock |

|

P5826.110.050 |

50 |

56 |

25 |

61 |

Ex-Stock |

|

P5826.110.063 |

63 |

65 |

33 |

71 |

Ex-Stock |

|

P5826.110.090 |

90 |

79 |

45 |

88 |

Ex-Stock |

|

P5826.110.125 |

125 |

87 |

63 |

99 |

Ex-Stock |

|

P5826.110.180 |

180 |

105 |

90 |

123 |

Ex-Stock |

|

P5826.110.250 |

250 |

130 |

125 |

155 |

Ex-Stock |

|

P5826.110.315 |

315 |

150 |

158 |

181 |

Ex-Stock |

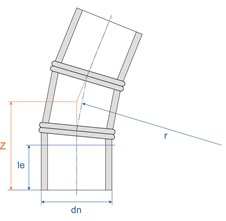

Blue / Purple 22º Segmented Spigot Bends / PN16 / SDR11

Fabricated two mitre spigot bends are manufactured from Mill-Pro M10 PE100 RC SDR11 blue or purple pipe and fabricated according to BS EN 12201-3, clause B.3, using butt weld techniques according to BS ISO 21307. They feature long spigots for electrofusion joining and 1D and 2D bar code stickers for complete product traceability. All elbows are sealed in individual plastic bags for protection on site.

Segmented bends are manufactured from a pipe, with cut angles ≤ 7.5º and therefore are not subject to pressure de-ration factor required in BS EN 12201 Clause B.3. Generally, the internal weld beads are removed where possible and external weld beads are not removed unless ordered otherwise.

Any bend angle from 16º to 30º can be custom manufactured. The standard angle for a two mitre bend is 22º with a radius of 2.5 x OD.

NOTE: The spigot ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes.

| Fabricated bends are made from pipe, so sizes up to dn1000 in PN16/SDR11 rating are available in blue or purple colour. | ||||||

| PN16 Purple | PN16 Blue | dn | le | r = 2.5 dn | z - 22º Double mitre | Availability in Hong Kong |

| P5K66.285.250 | P5K26.285.250 | 250 | 250 | 625 | 371 | 6-8 weeks |

| P5K66.285.315 | P5K26.285.315 | 315 | 300 | 788 | 453 | 6-8 weeks |

| P5K66.285.355 | P5K26.285.355 | 355 | 300 | 888 | 473 | 6-8 weeks |

| P5K66.285.450 | P5K26.285.450 | 450 | 300 | 1125 | 519 | 6-8 weeks |

| P5K66.285.500 | P5K26.285.500 | 500 | 350 | 1250 | 593 | 6-8 weeks |

| P5K66.285.560 | P5K26.285.560 | 560 | 350 | 1400 | 622 | 6-8 weeks |

| P5K66.285.630 | P5K26.285.630 | 630 | 350 | 1575 | 656 | 6-8 weeks |

| P5K66.285.710 | P5K26.285.710 | 710 | 350 | 1775 | 695 | 6-8 weeks |

| P5K66.285.800 | P5K26.285.800 | 800 | 350 | 2000 | 739 | 6-8 weeks |

| P5K66.285.900 | P5K26.285.900 | 900 | 400 | 2250 | 837 | 6-8 weeks |

| P5K66.285.1000 | P5K26.285.1000 | 1000 | 400 | 2500 | 886 | 6-8 weeks |

Blue / Purple 22º Segmented Spigot Bends / PN10 / SDR17

As above for PN16 bends, however, bends are manufactured from Mill-Pro M10E PE100 RC SDR17 blue or purple pipe. hence rated for PN10.

| Fully complies with WSD PS, however only where the engineer allows the use of PN10 fittings. | ||||||

| Sizes ≤ dn1600 and <dn355 available on request. | ||||||

| PN10 Purple | PN10 Blue | dn | le | r = 2.5 dn | z - 22º Double mitre | Availability in Hong Kong |

| P5K64.285.355 | P5K24.285.355 | 355 | 300 | 888 | 473 | 6-8 weeks |

| P5K64.285.450 | P5K24.285.450 | 450 | 300 | 1125 | 519 | 6-8 weeks |

| P5K64.285.500 | P5K24.285.500 | 500 | 350 | 1250 | 593 | 6-8 weeks |

| P5K64.285.560 | P5K24.285.560 | 560 | 350 | 1400 | 622 | 6-8 weeks |

| P5K64.285.630 | P5K24.285.630 | 630 | 350 | 1575 | 656 | 6-8 weeks |

| P5K64.285.710 | P5K24.285.710 | 710 | 350 | 1775 | 695 | 6-8 weeks |

| P5K64.285.800 | P5K24.285.800 | 800 | 350 | 2000 | 739 | 6-8 weeks |

| P5K64.285.900 | P5K24.285.900 | 900 | 400 | 2250 | 837 | 6-8 weeks |

| P5K64.285.1000 | P5K24.285.1000 | 1000 | 400 | 2500 | 886 | 6-8 weeks |

| P5K64.285.1200 | P5K24.285.1200 | 1200 | 400 | 3000 | 983 | 6-8 weeks |