Black 90º Bends

Black 90º Injection Moulded Electrofusion Elbows / PN16 / SDR11

Friatec's PE100 RC Injection moulded electrofusion elbows are suitable for fusing pipes from SDR11 to SDR17.6 Electrofusion sockets feature all the same performance benefits found in black couplers along with built-in reinforcement, so no de-ration is required.

NOTE: The pipe ends and sockets must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

| Subject to the Engineers approval, this product can be used in above-ground PN16 applications that require PN20 fittings for the purpose of thermal de-ration. Socket fittings do not require thermal de-ration as the fitting is reinforced, due to sockets overlapping the spigots. This statement is only applicable for fittings operating at up to PN16 Maximum Operating Pressure. | |||||||

|

Product Code |

dn |

D1 |

L |

L1 |

L2 |

Z |

Availability in Hong Kong |

|

P3316.115.025 |

25 |

37 |

73 |

40 |

19 |

15 |

8-12 Weeks |

|

P3316.115.032 |

32 |

43 |

82 |

44 |

21 |

16 |

8-12 Weeks |

|

P3316.115.050 |

50 |

66 |

113 |

55 |

32 |

26 |

8-12 Weeks |

|

P3316.115.063 |

63 |

83 |

136 |

62 |

30 |

33 |

8-12 Weeks |

|

P3316.115.090 |

90 |

115 |

202 |

75 |

45 |

65 |

8-12 Weeks |

|

P3316.115.125 |

125 |

157 |

254 |

87 |

44 |

89 |

8-12 Weeks |

|

P3316.115.180 |

180 |

228 |

354 |

94 |

65 |

146 |

8-12 Weeks |

Black 90º Injection Moulded Electrofusion Elbows XL / PN16 / SDR11

Friatec's PE100 XL range of electrofusion elbows are suitable for fusing pipes from SDR11 to SDR17.6 Electrofusion sockets feature all the same performance benefits found with black couplers along with built-in reinforcement, so no de-ration is required. XL fittings have fused eyebolt holes for ease of handling on site.

NOTE: The electrofusion socket and pipe ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

Frialen Black Electrofusion elbows are made in Germany.

| Typically blue moulded spigot elbows and couplers would be used in these sizes in Hong Kong | |||||||

|

Product Code |

dn |

D1 |

L |

L1 |

L2 |

Z |

Availability in Hong Kong |

|

P3316.115.250 |

250 |

310 |

534 |

128 |

80 |

251 |

8-12 Weeks |

|

P3316.115.315 |

315 |

396 |

677 |

150 |

80 |

329 |

8-12 Weeks |

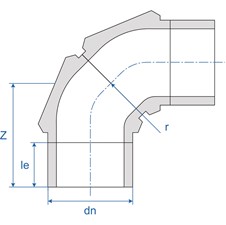

Black 90º Segmented Spigot Bends / PN16 / SDR11

Black segmented spigot bends are available in all sizes and pressure ratings, however, PN10 and PN16 bends are not listed in our water section, as typically Blue or Purple fabricated bends would be used in hong kong. For above-ground applications requiring thermal de-ration, PN20 / SDR9 black bends would be used. A range of black fabricated spigot bends can be found in our wastewater section here.

Black 90º Segmented Spigot Bends / PN20 / SDR9

PN20 / SDR9 segmented bends can be used for above-ground installations exposed to direct sunlight in a PN16 pipeline, where the pipes surface temperature may exceed 40ºC. The higher pressure rating allows for thermal de-ration due to prolonged elevated operating temperatures.

Mill-Pro's fabricated spigot bends are manufactured from Mill-Pro M100 PE100 RC SDR9 black pipe and fabricated according to BS EN 12201-3, clause B.3, using butt weld techniques according to BS ISO 21307. They feature long spigots for electrofusion or butt fusion joining and 1D and 2D bar code stickers for complete product traceability. All bends are sealed in individual plastic bags for protection on site.

Segmented bends are manufactured from a pipe, with cut angles ≤ 7.5º and therefore are not subject to pressure de-ration factor required in BS EN 12201 Clause B.3. Generally, the internal weld beads are removed where possible and external weld beads are not removed unless ordered otherwise.

Any bend angle from 46º to 90º can be custom manufactured, however, the number of mitres required increases as the bend angle increases. In order to maintain a cut angle ≤ 7.5º, the angle for a four mitre bend is between 46º to 60º, for a five mitre bend between 61º to 75º and for a six mitre bend between 76º to 90º. All bends have a radius of 2.5 x OD.

NOTE: The spigot ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes.

| dn800 is the largest size bends available in SDR9. | |||||

| Supply of Bends in sizes ≥ dn250 is subject to the availability of SDR9 pipe. | |||||

|

Product Code |

dn |

le |

r = 2.5 dn |

Z – 90º 6 mitre |

Availability in Hong Kong |

|

P5817.289.090 |

90 |

150 |

225 |

280 |

4-6 Weeks |

|

P5817.289.125 |

125 |

150 |

313 |

330 |

4-6 Weeks |

|

P5817.289.180 |

180 |

150 |

450 |

410 |

4-6 Weeks |

|

P5817.289.250 |

250 |

250 |

625 |

611 |

Contact Us |

|

P5817.289.315 |

315 |

300 |

788 |

755 |

Contact Us |

|

P5817.289.355 |

355 |

300 |

888 |

1188 |

Contact Us |

|

P5817.289.450 |

450 |

300 |

1125 |

1425 |

Contact Us |

|

P5817.289.500 |

500 |

350 |

1250 |

1600 |

Contact Us |

|

P5817.289.560 |

560 |

350 |

1400 |

1750 |

Contact Us |

|

P5817.289.630 |

630 |

350 |

1575 |

1925 |

Contact Us |

|

P5817.289.710 |

710 |

350 |

1775 |

2125 |

Contact Us |

|

P5817.289.800 |

800 |

350 |

2000 |

2350 |

Contact Us |

Black 90º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated 90º elbows are manufactured by factory butt welding two 45º elbows together. Elbows are machined from black PE100+ compound. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below show standard 90º elbow with a radius of ~0.5xOD for reference.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | d1 | le1 | r | z1 - 90º | Availability in Hong Kong |

| P5314.81.355 | P5316.81.355 | 355 | 200 | 177 | 560 | 14-16 weeks |

| P5314.81.400 | P5316.81.400 | 400 | 300 | 200 | 684 | 14-16 weeks |

| P5314.81.450 | P5316.81.450 | 450 | 300 | 225 | 709 | 14-16 weeks |

| P5314.81.500 | P5316.81.500 | 500 | 300 | 250 | 753 | 14-16 weeks |

| P5314.81.560 | P5316.81.560 | 560 | 300 | 280 | 828 | 14-16 weeks |

| P5314.81.630 | P5316.81.630 | 630 | 300 | 315 | 874 | 14-16 weeks |

| P5314.81.710 | P5316.81.710 | 710 | 500 | 355 | 1111 | 14-16 weeks |

| P5314.81.800 | P5316.81.800 | 800 | 500 | 400 | 1149 | 14-16 weeks |

| P5314.81.900 | P5316.81.900 | 900 | 500 | 450 | 1327 | 14-16 weeks |

| P5314.81.1000 | P5316.81.1000 | 1000 | 500 | 500 | 1386 | 14-16 weeks |

| P5314.81.1200 | - | 1200 | 500 | 600 | 1403 | 14-16 weeks |