45º Bends

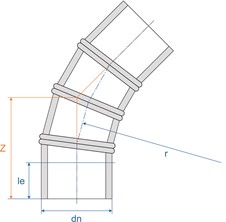

45º Segmented Spigot CCTV Bends / PN10 / SDR17 / Twin Stripe

Manufactured from Mill-Pro M90SE PE100 RC SDR17 CCTV pipe and fabricated according to BS EN 12201-3, clause B.3, using butt weld techniques according to BS ISO 21307. They feature long spigots for electrofusion or butt fusion joining and 1D and 2D bar code stickers for complete product traceability.

Segmented bends are manufactured from a pipe, with cut angles ≤ 7.5º and therefore are not subject to pressure de-ration factor required in BS EN 12201 Clause B.3. Generally, the internal weld beads are removed where possible and external weld beads are not removed unless ordered otherwise.

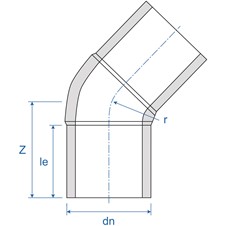

Any bend angle from 31º to 45º can be custom manufactured, standard angle for a three mitre bend is 45º with a radius of 2.5 x OD, as given in the table below.

NOTE: The spigot ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes.

|

Larger sizes to dn2000 in PN ratings from PN4 to PN10 are available in M100E pipe, subject to pipe availability. |

||||||

|

Bends with brown or green twin stripes can only be supplied when also supplying the matching pipe. |

||||||

| To transport large bore bends, these may need to be made in sections and joined on site. | ||||||

|

PN10 SDR17 Twin Brown Sewer |

PN10 SDR17 Twin Green Stormwater |

dn |

le |

r = 2.5 dn |

Z - 45º Three mitre |

Availability in Hong Kong |

|

P5Q54.287.110 |

P5QG4.287.110 |

110 |

150 |

275 |

264 |

6-8 weeks |

|

P5Q54.287.160 |

P5QG4.287.160 |

160 |

150 |

400 |

316 |

6-8 weeks |

|

P5Q54.287.225 |

P5QG4.287.225 |

225 |

150 |

563 |

383 |

6-8 weeks |

|

P5Q54.287.250 |

P5QG4.287.250 |

250 |

250 |

625 |

509 |

6-8 weeks |

|

P5Q54.287.280 |

P5QG4.287.280 |

280 |

250 |

700 |

540 |

6-8 weeks |

|

P5Q54.287.355 |

P5QG4.287.355 |

355 |

300 |

888 |

668 |

6-8 weeks |

|

P5Q54.287.400 |

P5QG4.287.400 |

400 |

300 |

1000 |

714 |

6-8 weeks |

|

P5Q54.287.450 |

P5QG4.287.450 |

450 |

300 |

1125 |

766 |

6-8 weeks |

|

P5Q54.287.500 |

P5QG4.287.500 |

500 |

350 |

1250 |

868 |

6-8 weeks |

|

P5Q54.287.560 |

P5QG4.287.560 |

560 |

350 |

1400 |

930 |

6-8 weeks |

|

P5Q54.287.630 |

P5QG4.287.630 |

630 |

350 |

1575 |

1002 |

6-8 weeks |

|

P5Q54.287.710 |

P5QG4.287.710 |

710 |

350 |

1775 |

1085 |

6-8 weeks |

|

P5Q54.287.800 |

P5QG4.287.800 |

800 |

350 |

2000 |

1178 |

6-8 weeks |

|

P5Q54.287.900 |

P5QG4.287.900 |

900 |

400 |

2250 |

1332 |

6-8 weeks |

|

P5Q54.287.1000 |

P5QG4.287.1000 |

1000 |

400 |

2500 |

1436 |

6-8 weeks |

|

P5Q54.287.1200 |

P5QG4.287.1200 |

1200 |

400 |

3000 |

1643 |

6-8 weeks |

|

P5Q54.287.1400 |

P5QG4.287.1400 |

1400 |

550 |

3500 |

2000 |

6-8 weeks |

|

P5Q54.287.1600 |

P5QG4.287.1600 |

1600 |

550 |

4000 |

2207 |

6-8 weeks |

45º Segmented Spigot CCTV Bends / PN16 / SDR11 / Twin Stripe

As above, segmented bends fabricated from PN16 / SDR 11 CCTV twin stripe pipe.

|

dn1000 is the largest size pipe and therefore is the largest bend size available in PN16/SDR11. |

||||||

|

Other PN ratings from PN4 to PN25 are available on request, subject to pipe availability. |

||||||

|

Bends with brown or green twin stripes can only be supplied when also supplying the matching pipe. |

||||||

| To transport large bore bends, these may need to be made in sections and joined on site. | ||||||

|

PN16 SDR11 Twin Brown Sewer |

PN16 SDR11 Twin Green Stormwater |

dn |

le |

r = 2.5 dn |

Z - 45º Three mitre |

Availability in Hong Kong |

|

P5Q56.287.110 |

P5QG6.287.110 |

110 |

150 |

275 |

264 |

6-8 weeks |

|

P5Q56.287.160 |

P5QG6.287.160 |

160 |

150 |

400 |

316 |

6-8 weeks |

|

P5Q56.287.225 |

P5QG6.287.225 |

225 |

150 |

563 |

383 |

6-8 weeks |

|

P5Q56.287.250 |

P5QG6.287.250 |

250 |

250 |

625 |

509 |

6-8 weeks |

|

P5Q56.287.280 |

P5QG6.287.280 |

280 |

250 |

700 |

540 |

6-8 weeks |

|

P5Q56.287.355 |

P5QG6.287.355 |

355 |

300 |

888 |

668 |

6-8 weeks |

|

P5Q56.287.400 |

P5QG6.287.400 |

400 |

300 |

1000 |

714 |

6-8 weeks |

|

P5Q56.287.450 |

P5QG6.287.450 |

450 |

300 |

1125 |

766 |

6-8 weeks |

|

P5Q56.287.500 |

P5QG6.287.500 |

500 |

350 |

1250 |

868 |

6-8 weeks |

|

P5Q56.287.560 |

P5QG6.287.560 |

560 |

350 |

1400 |

930 |

6-8 weeks |

|

P5Q56.287.630 |

P5QG6.287.630 |

630 |

350 |

1575 |

1002 |

6-8 weeks |

|

P5Q56.287.710 |

P5QG6.287.710 |

710 |

350 |

1775 |

1085 |

6-8 weeks |

|

P5Q56.287.800 |

P5QG6.287.800 |

800 |

350 |

2000 |

1178 |

6-8 weeks |

|

P5Q56.287.900 |

P5QG6.287.900 |

900 |

400 |

2250 |

1332 |

6-8 weeks |

|

P5Q56.287.1000 |

P5QG6.287.1000 |

1000 |

400 |

2500 |

1436 |

6-8 weeks |

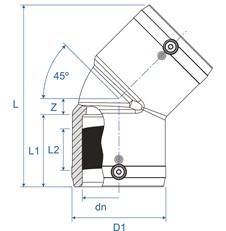

Black 45º Injection Moulded Electrofusion Elbows / PN10-16 / SDR17-11

Friatec's PE100 RC Injection moulded electrofusion elbows are suitable for fusing pipes from SDR11 to SDR17.6 Electrofusion sockets feature all the same performance benefits found in black couplers along with built-in reinforcement, so no de-ration is required.

NOTE: The pipe ends and sockets must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

Frialen Black Electrofusion elbows are made in Germany.

|

Product Code |

dn |

D1 |

L |

L1 |

L2 |

Z |

Availability in Hong Kong |

|

P3316.119.063 |

63 |

82 |

158 |

62 |

34 |

14 |

8-12 Weeks |

|

P3316.119.090 |

90 |

115 |

232 |

79 |

45 |

35 |

8-12 Weeks |

|

P3316.119.110 |

110 |

138 |

265 |

85 |

50 |

41 |

8-12 Weeks |

|

P3316.119.125 |

125 |

157 |

279 |

87 |

44 |

46 |

8-12 Weeks |

|

P3316.119.160 |

160 |

207 |

377 |

92 |

44 |

88 |

8-12 Weeks |

|

P3316.119.180 |

180 |

228 |

382 |

97 |

65 |

83 |

8-12 Weeks |

|

P3316.119.200 |

200 |

254 |

415 |

106 |

54 |

87 |

8-12 Weeks |

|

P3316.119.225 |

225 |

280 |

450 |

112 |

66 |

98 |

Ex-Stock |

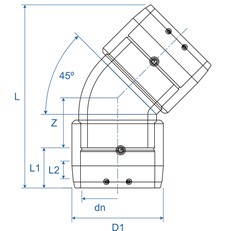

Black 45º Injection Moulded Electrofusion Elbows XL / EF / PN10-16 / SDR17-11

Friatec's PE100 XL range of electrofusion elbows are suitable for fusing pipes from SDR11 to SDR17.6 Electrofusion sockets feature all the same performance benefits found with black couplers along with built-in reinforcement, so no de-ration is required. XL fittings have fused eyebolt holes for ease of handling on site.

NOTE: The electrofusion socket and pipe ends must be prepared in accordance with the general installation instructions using a spigot mechanical peeler, 90% Isopropyl alcohol wipes and we recommend using the Friamat fusion control unit to achieve correct preheating and logging the full range of weld data available.

Frialen Black Electrofusion elbows are made in Germany.

|

Product Code |

dn |

D1 |

L |

L1 |

L2 |

Z |

Availability in Hong Kong |

|

P3316.119.250 |

250 |

310 |

621 |

128 |

80 |

176 |

8-12 Weeks |

|

P3316.119.280 |

280 |

350 |

702 |

139 |

84 |

205 |

8-12 Weeks |

|

P3316.119.315 |

315 |

396 |

755 |

150 |

80 |

215 |

8-12 Weeks |

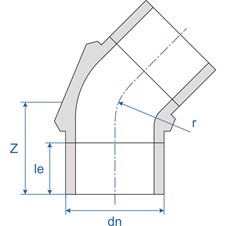

Black 45º Fabricated Spigot Elbows / PN10-PN16 / SDR17-SDR11

Fabricated elbows are manufactured from black PE100+ compound. They feature long spigots for electrofusion or butt fusion joining on site. Any fabricated elbow angle from 1º to 45º can be manufactured. Tables below show standard 45º elbow with a radius of ~0.5xOD for reference.

| Custom fabricated elbows do not require pipe to manufacture. Individual elbows may be ordered in any angle. | ||||||

| PN10 SDR17 | PN16 SDR11 | dn | le | r | z - 45º | Availability in Hong Kong |

| P5314.79.355 | P5316.79.355 | 355 | 200 | 177 | 365 | 14-16 weeks |

| P5314.79.400 | P5316.79.400 | 400 | 300 | 200 | 475 | 14-16 weeks |

| P5314.79.450 | P5316.79.450 | 450 | 300 | 225 | 485 | 14-16 weeks |

| P5314.79.500 | P5316.79.500 | 500 | 350 | 250 | 555 | 14-16 weeks |

| P5314.79.560 | P5316.79.560 | 560 | 350 | 280 | 590 | 14-16 weeks |

| P5314.79.630 | P5316.79.630 | 630 | 350 | 315 | 610 | 14-16 weeks |

| P5314.79.710 | P5316.79.710 | 710 | 500 | 355 | 775 | 14-16 weeks |

| P5314.79.800 | P5316.79.800 | 800 | 500 | 400 | 790 | 14-16 weeks |

| P5314.79.900 | P5316.79.900 | 900 | 500 | 450 | 875 | 14-16 weeks |

| P5314.79.1000 | P5316.79.1000 | 1000 | 500 | 500 | 900 | 14-16 weeks |

| P5314.79.1200 | - | 1200 | 500 | 600 | 900 | 14-16 weeks |

| P5314.79.1400 | - | 1400 | 500 | 700 | 1000 | 14-16 weeks |

Black 45º Injection Moulded Spigot Elbows

Mill-Pro supplies a small range of PE100+ Black Injection moulded spigot elbows. It should be noted in the table below fitting dimension 'le' marked with * do not meet the required minimum spigot length for use as long spigot fittings, given in BS EN 12201-3 Table 3, 'Tubular length'. These fittings DO meet the standard for use as a butt weld fittings and they meet all other requirements given in the standard.

All fittings given in the table below have sufficient spigot length required for fusion using Friatec electrofusion couplers. However, certification cannot currently be provided for the fittings compliance to BS EN 12201-3 when used as a long spigot elbow for electrofusion joining.

| *Spigot lengths suitable for Mill-Pro supplied PN10 EF couplers but shorter than L2 in BSEN 12201-3 table 3 | ||||||

| SDR17 PN10 | SDR11 PN16 | dn | le | r | z | Availability in Hong Kong |

| P5314.119.063 | P5316.119.063 | 63 | 63 | 32 | 89 | 4-6 weeks |

| P5314.119.090 | P5316.119.090 | 90 | 79 | 45 | 105 | 4-6 weeks |

| P5314.119.110 | P5316.119.110 | 110 | 82 | 55 | 118 | 4-6 weeks |

| P5314.119.125 | P5316.119.125 | 125 | 87 | 63 | 125 | 4-6 weeks |

| P5314.119.160 | P5316.119.160 | 160 | 98 | 80 | 142 | 4-6 weeks |

| P5314.119.180 | P5316.119.180 | 180 | *100 | 90 | 120 | 4-6 weeks |

| P5314.119.200 | P5316.119.200 | 200 | 112 | 100 | 162 | 4-6 weeks |

| P5314.119.225 | P5316.119.225 | 225 | 115 | 113 | 155 | 4-6 weeks |

| P5314.119.250 | P5316.119.250 | 250 | 129 | 125 | 190 | 4-6 weeks |

| P5314.119.280 | P5316.119.280 | 280 | 148 | 140 | 230 | 4-6 weeks |

| P5314.119.315 | P5316.119.315 | 315 | 150 | 158 | 240 | 4-6 weeks |

| P5314.119.355 | P5316.119.355 | 355 | 164 | 178 | 270 | 4-6 weeks |

| P5314.119.400 | P5316.119.400 | 400 | *150 | 200 | 255 | 4-6 weeks |

| P5314.119.450 | - | 450 | *170 | 225 | 290 | 4-6 weeks |

| P5314.119.500 | - | 500 | *205 | 250 | 320 | 4-6 weeks |

| P5314.119.560 | - | 560 | *200 | 280 | 345 | 4-6 weeks |

| P5314.119.630 | - | 630 | *220 | 315 | 370 | 4-6 weeks |

Three Mitre Custom Segment Spigot Bends / PN4-25 / SDR41-7.4

As above, three mitre segmented bends are manufactured from pipes supplied for the contract, such as M90SE or M100E, in any angle from 31º to 45º with radii from 1.5 - 2.5xOD. Bend sizes are only limited by the pipes size and rating. See M100 pipe tables for the maximum pipe DN/OD at a given SDR rating. Contact us for specific requirements.